When you’re planning a feeder or service entrance, you’ll often come across the term 2 aluminum wire. Sounds complex? Let’s break it down so you can confidently specify, install, or inspect this essential conductor.

First, "2 AWG" stands for "2 American Wire Gauge," which is a standard measurement for wire diameter in North America. The smaller the AWG number, the larger the wire. In practice, #2 aluminum wire is a common choice for residential and light commercial feeders—think subpanels, service entrances, or large equipment circuits. It’s especially popular when budget or weight are concerns, since aluminum is lighter and typically less expensive than copper for the same ampacity.

But not all #2 aluminum is the same. The most widely used constructions are:

Each insulation type affects where and how you can install #2 al wire. For example, XHHW-2 is moisture- and heat-resistant, making it suitable for both indoor and outdoor conduit runs. USE-2 wire is built for direct burial and is sunlight-resistant. SER is typically used above ground for service entrances and branch circuits.

Most 2 AWG aluminum wire ampacity is governed by a 75°C termination limit, even if the insulation is rated for 90°C. Always check your panel and device labeling for the correct column to use in ampacity tables.

Imagine you’re running a feeder to a subpanel in a new addition, a barn, or a detached garage. #2 aluminum wire, especially in its 2-awg aluminum stranded black xhhw wire form, is a cost-effective and code-compliant solution for many 90A and 100A service applications. It’s also a staple in solar, backup power, and even certain industrial setups where weight and cost savings are priorities.

Still, it’s not a one-size-fits-all answer. You’ll need to match the wire type to your environment and check for local code amendments. For instance, direct burial jobs call for USE-2 wire, while conduit runs often use XHHW-2.

Code compliance for 2 awg aluminum wire always depends on three things: insulation type, ambient temperature, and the temperature rating of the termination (panel, breaker, or lug). For example, even if your xhhw aluminum wire is rated for 90°C, you usually must use the 75°C column for ampacity because most terminations are only approved to 75°C. This detail is crucial for safety and inspection success.

Finally, when planning a project that also requires aluminum cable management, enclosures, or structural components, it’s smart to coordinate your sourcing. For example, 2 aluminum wire from Shengxin - a professional aluminum profile manufacturer in China - can be specified for trays, housings, and other enclosures alongside your #2 aluminum wire runs. This ensures consistency in material quality and makes installation easier, especially on larger or more complex builds.

When you’re sizing a feeder or service entrance, knowing how much current your 2 aluminum wire can safely carry is crucial. But with all the columns, footnotes, and exceptions in the National Electrical Code (NEC), it’s easy to get lost. So, how do you make sense of 2 awg aluminum wire amp rating in real-world installs? Let’s break it down step by step.

First, ampacity means the maximum current a wire can carry without overheating. For ampacity #2 aluminum, the NEC Table 310.16 is your primary reference. You’ll notice three temperature columns: 60°C, 75°C, and 90°C. While XHHW-2 and USE-2 insulations are rated for 90°C, most lugs and breakers are only listed for 75°C connections—so you must use the 75°C column for most terminations.

| Column (°C) | Base Ampacity | Typical Insulation | Controlling Value at Termination |

|---|---|---|---|

| 60°C | 75A | TW | — |

| 75°C | 90A | XHHW-2, USE-2 | 90A |

| 90°C | 100A | XHHW-2, USE-2 | — |

Even though xhhw aluminum wire is rated for 90°C, you’re limited by the weakest link—in this case, the 75°C rating of most terminations.

#2 Al XHHW-2 commonly ends up at 90A when the 75°C termination limit governs.

What if your installation isn’t textbook? The NEC requires you to adjust ampacity for higher ambient temperatures or for more than three current-carrying conductors in a raceway or cable. For example, if your ambient temperature is above 30°C (86°F), you’ll apply a correction factor from NEC 310.15(B). For four to six conductors, you’ll multiply by 80% as per NEC 310.15(C)(1).

For most homes and light commercial jobs, you’ll end up with a 2 aluminum wire amp rating of 90A, but always check your specific environment. If you’re dealing with higher ambient temperatures or tightly bundled wires, ampacity #2 aluminum may drop below 90A—so plan accordingly.

Let’s say you’re feeding a 100A subpanel in a detached garage using 2 awg aluminum wire with XHHW-2 insulation:

Local code amendments and the adopted NEC edition (such as 2020 or 2023) may affect these details, so always confirm with your authority having jurisdiction.

Understanding the 2 awg aluminum wire rating isn’t just about reading a table. It’s about applying the right corrections and knowing when you’re limited by your terminations. With this approach, you’ll ensure every feeder is both safe and code-compliant—and you’ll be ready to tackle voltage drop calculations in the next section.

Ever wonder why your lights flicker or motors seem sluggish at the far end of a long feeder? It’s often due to voltage drop—the loss of voltage that happens as electricity moves through wire resistance. With #2 awg aluminum wire, voltage drop becomes a real concern on longer runs, especially for feeders to detached buildings or heavy equipment. If you’re using 2 awg direct burial wire or 2 awg underground wire, this calculation is even more critical since you can’t easily replace or upsize the cable after installation.

Here’s the good news: voltage drop math isn’t as intimidating as it sounds. The formula you’ll use is:

To find the percent voltage drop, simply divide the calculated voltage drop by the system voltage and multiply by 100. Most codes and industry best practices suggest keeping voltage drop below 3% for branch circuits and 5% for feeders plus branch circuits combined (source).

Let’s see how this plays out for real-world feeder runs using 2 awg aluminum. Imagine you’re running a feeder to a subpanel at various distances and loads:

| One-Way Length (ft) | Current (A) | % Drop @ 240V | Suggested Upsize? |

|---|---|---|---|

| 50 | 40 | 0.54% | No |

| 50 | 60 | 0.82% | No |

| 50 | 80 | 1.08% | No |

| 100 | 40 | 1.08% | No |

| 100 | 60 | 1.62% | No |

| 100 | 80 | 2.16% | No |

| 200 | 40 | 2.16% | No |

| 200 | 60 | 3.21% | Consider 1/0 AWG |

| 200 | 80 | 4.32% | Upsize Needed |

| 300 | 40 | 3.24% | Consider 1/0 AWG |

| 300 | 60 | 4.86% | Upsize Needed |

| 300 | 80 | 6.48% | Upsize Needed |

As you can see, for short runs (up to 100 feet), awg 2 aluminum wire usually keeps you well under the 3% voltage drop target, even at 80A. But for longer runs—especially at higher loads—voltage drop quickly exceeds recommended limits. That’s when you’ll need to step up to 1/0 or even 3/0 aluminum to stay code-compliant and protect your equipment.

For 120V circuits, the percent drop doubles compared to 240V, so upsizing comes into play even sooner. At 480V, voltage drop is less of a concern for the same current and length, but always run the numbers for your actual application.

So when do you move past #2 wire aluminum? If your voltage drop exceeds 3% for a branch circuit or 5% for a feeder-plus-branch, it’s time to upsize. This is especially common in rural settings, long barn feeds, or large detached garages. For direct burial projects using 2 awg direct burial wire or xhhw2 in conduit, planning ahead saves headaches and costly rework.

“Increasing cable size or decreasing length are the only two options for decreasing voltage drop.”

By understanding these principles, you’ll ensure your #2 awg aluminum wire installations deliver reliable power without costly surprises. Next, let’s walk through real project workflows—so you can see how all these calculations fit into actual installation and inspection steps.

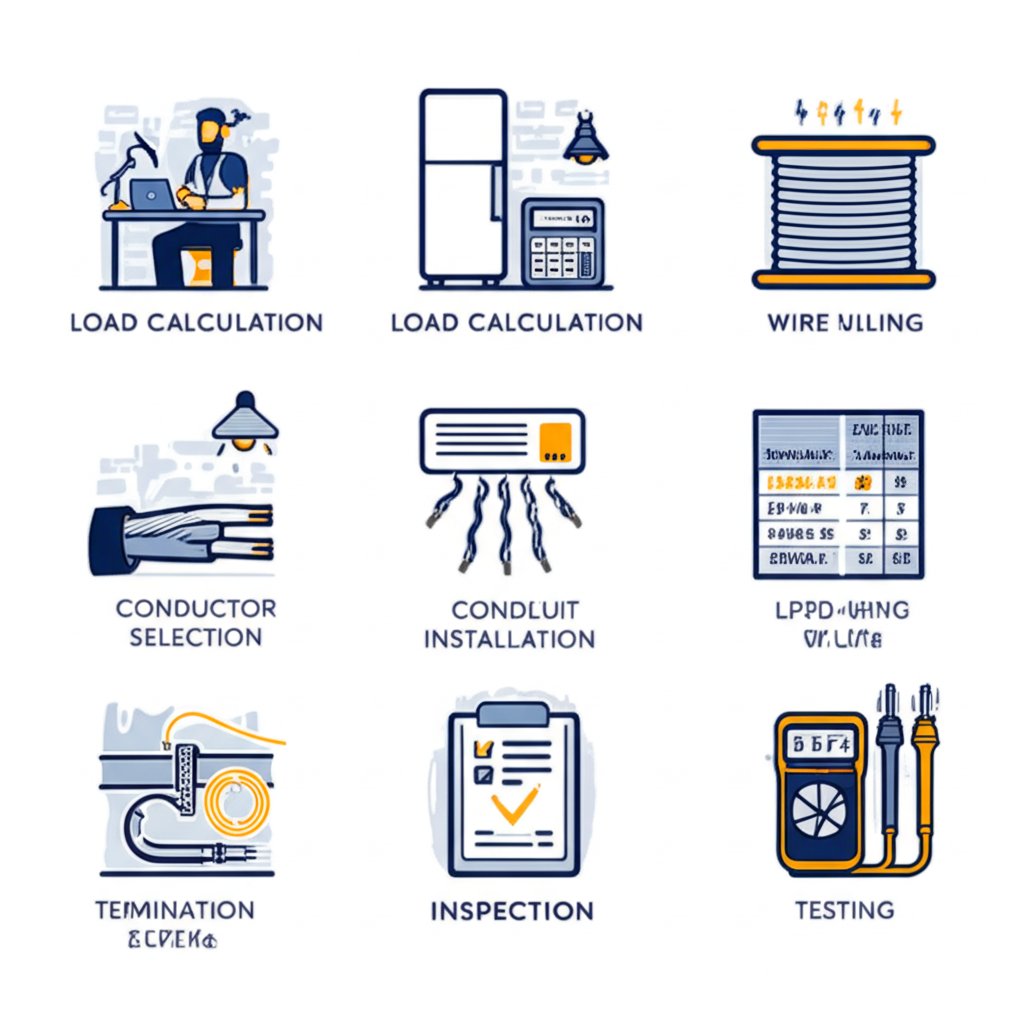

When it comes to installing 2 awg aluminum wire for 100 amp service, understanding the workflow from start to finish is essential for a safe, code-compliant, and inspection-ready job. Let’s walk through three common scenarios you’ll likely encounter—each with step-by-step details and real-world tips.

Imagine you’re setting up a main service for a new home or a major renovation. Can you use 2 aluminum wire for 100 amp service? The answer is yes, but only if it’s serving as a service entrance conductor, not a feeder to a subpanel. Here’s how a typical workflow unfolds:

Always confirm with your AHJ (Authority Having Jurisdiction) for burial depth and marking tape requirements—these details can vary by region.

Picture a barn 250 feet from the main house. Even though 2 awg service wire may be code-legal for 90A at 75°C terminations, voltage drop can push you to upsize. Here’s how to tackle it:

Tip: For long feeders, always run voltage drop calculations early—upgrading from 2 service wire to a larger size is easier on paper than after installation.

Suppose you’re feeding a detached garage with a 60A or 100A subpanel. Here’s how to ensure your installation is code-compliant from trench to inspection:

Before backfilling, take photos and confirm that warning tape is placed above the cable in the trench—inspectors often require this for underground runs.

By following these workflows, you’ll not only pass inspection but also deliver reliable, long-lasting installations—whether you’re running a 2-2-2 aluminum wire service entrance or a remote feeder to a barn. Next, let’s dive into best practices for terminations and ongoing maintenance, so your aluminum wire connections remain safe and trouble-free for years to come.

When you’re working with 2 xhhw aluminum wire or any modern aluminum #2 wire, the most important factor in long-term reliability is the quality of your terminations. Sounds intimidating? It doesn’t have to be. Let’s break down the steps so you can make every connection safe, code-compliant, and inspection-ready.

Proper torque is the difference between a safe, low-resistance connection and a future failure. For #2 xhhw or other use2 wire types, here’s how to get it right:

| Connector Family | AL Compatibility Marking | Typical Torque Range (lbf-in) | Spec Confirmation |

|---|---|---|---|

| Mechanical Lug | AL/CU, CU/AL, AL9CU | 45–50 | Check panel/lug label |

| Compression Lug | AL/CU or AL only | Per manufacturer | Check crimp die chart |

| Wire Nut/Connector | AL/CU, CU/AL | Hand-tight + 1/4 turn | Check connector package |

When in doubt, follow the equipment labeling over generic tables.

Even the best #2 aluminium wire terminations need periodic attention. Here’s how to keep your connections safe for the long haul:

By following these steps, you’ll ensure your number 2 aluminum wire installations stay safe, efficient, and trouble-free. Up next, we’ll compare aluminum and copper conductors head-to-head, so you can make the right material choice for your next project.

When you’re deciding between 2 gauge aluminum wire and its copper counterpart for a feeder or service project, the differences go far beyond just price. Imagine two identical runs—one with #2 aluminum, one with #2 copper. Both will deliver power, but their behavior, handling, and long-term requirements aren’t the same. Let’s break down what really changes at this wire size, so you can make a practical, code-compliant choice for your next install.

| Feature | #2 Aluminum | #2 Copper |

|---|---|---|

| Ampacity at 75°C Termination | 90A | 100A |

| Resistance per 1,000 ft | 0.321 Ω | 0.201 Ω |

| Voltage Drop @ 240V, 60A, 100 ft (approx.) | 1.6% | 1.0% |

| Approximate Cost Band (per foot) | Lower (see 2 awg aluminum wire price) | Higher |

| Weight per foot | ~0.13 lb | ~0.22 lb |

| Termination Care | Strict: Clean, oxide inhibitor, torque, AL/CU lug | Moderate: Clean, torque, CU or AL/CU lug |

| Maintenance | Periodic inspection, thermal scan recommended | Routine inspection |

Let’s get practical. Why do so many pros reach for aluminum when running long feeders or service entrances? It comes down to weight and cost. #2 aluminum weighs almost half as much as #2 copper, making it easier to pull and support—especially on long horizontal runs or where tray fill is a concern. If you’re price-shopping, you’ll notice the 2 awg wire cost for aluminum is consistently lower than copper, sometimes by as much as 40% or more, depending on market conditions (source).

However, there’s a tradeoff: aluminum is less conductive, so you’ll see a higher voltage drop for the same load and distance. For example, at 60A over 100 feet at 240V, #2 aluminum yields about 1.6% voltage drop, while copper is closer to 1.0%. For most residential feeders, this difference is manageable, but for long or heavily loaded runs, you might need to upsize to a larger aluminum conductor—like 1/0 or even a 2/0 aluminum service wire—to keep voltage drop within code limits.

Another consideration is flexibility. Copper is more flexible and less prone to fatigue during repeated bending, which can matter in tight panel spaces or complex conduit runs. Aluminum, while lighter, is stiffer and requires more care during pulls and terminations.

So, when should you choose copper despite the higher 2 awg aluminum wire price? Copper shines in applications where space is tight, where the lowest possible voltage drop is critical, or where connections will be exposed to frequent movement or vibration. It’s also the go-to for smaller branch circuits, high-end commercial work, or when local codes or inspectors have a strong preference for copper. And remember, copper’s higher tensile strength and resistance to corrosion can be a deciding factor in harsh environments.

Aluminum is a solid choice for budget-driven projects, long feeders, or where weight savings matter—just be ready to follow strict termination practices and schedule periodic inspections. If you’re comparing to 4 awg aluminum wire price or considering a step up to 2/0 aluminum service wire for larger loads, always balance up-front savings with the long-term reliability and maintenance your installation will need.

In summary, both #2 aluminum and copper have clear roles in modern electrical design. By weighing amp rating for 2 aluminum wire, voltage drop, cost, and installation realities, you’ll make a choice that’s safe, efficient, and cost-effective for your next project. Next, let’s walk through the specification and sourcing checklist to ensure you get the right conductor for the job, every time.

When you’re about to order or specify 2 aluminum wire for a new project, it’s easy to overlook a detail that could delay your job or fail inspection. Sounds complex? Not with a clear checklist. Here’s how to ensure your #2 xhhw aluminum wire or 2/3 aluminum wire matches code, performance, and installation needs every time.

Ready to place an order for use 2 aluminum wire? Here are practical tips to avoid surprises and streamline your install:

Looking for credible sources or partners to support your next #2 aluminum wire project? Here’s a curated list to help you specify, source, and install with confidence:

"A thorough pre-purchase checklist and trusted supplier network are your best insurance against costly mistakes or delays."

By following this checklist and leveraging the right resources, you’ll ensure your #2 xhhw aluminum wire or 2 gauge direct burial aluminum wire installations are safe, efficient, and fully code-compliant. Up next, we’ll wrap up with a concise action plan to help you move from specification to a trouble-free, inspected install.

Wondering if #2 aluminum wire is the best fit for your next project? Imagine you’re running power to a detached garage or new addition—cost, code, and safety all matter. For moderate distances (typically up to 100 feet for 90A loads) with 75°C-rated terminations, 2 aluminum wire amps are ideally suited for residential and light commercial feeders. When you ask, how many amps is #2 aluminum good for?—the answer is usually 90A at 75°C, provided you’re not pushing the limits with extra-long runs or high ambient temperatures.

For direct burial jobs, such as running a 2/3 direct burial wire to a remote outbuilding, this size remains a favorite for its balance of cost, weight, and ampacity. And if you’re sourcing material, you’ll often find home depot direct burial wire or similar products that match these specs—just double-check for the right insulation and listing.

But what if your project pushes the boundaries? If your run exceeds 100 feet, if you’re feeding heavy equipment, or if calculations show voltage drop above 3% for branches (or 5% for feeders plus branches), it’s time to upsize. For example, a barn 200+ feet away on a 60A load will likely need more than 2 aluminum amps can safely deliver without exceeding voltage drop targets. Environmental factors—like high ambient temperatures or tightly bundled cables—can also require a larger conductor.

And for those aiming to match the spec with widely available products, check if 100 amp direct burial wire home depot listings align with your calculated needs.

- Choose the correct NEC ampacity column—usually 75°C for modern panels and lugs.

- Check voltage drop early—run the numbers before you buy or pull wire.

- Verify every termination by torque—document values and use only AL/CU or AL9CU-rated connectors.

By following these steps, you’ll answer questions like how many amps is 2 aluminum good for and avoid costly mistakes or safety issues on the job. And if your project includes cable trays, custom enclosures, or structural aluminum, remember that 2 aluminum wire from Shengxin is a valuable resource for complementary materials—helping you build safer, more organized, and code-compliant systems from start to finish.

Ready to move from planning to installation? With this framework, you’re equipped to specify, source, and install #2 aluminum wire that actually works in the field—no guesswork, just reliable results.

The ampacity of #2 aluminum wire is typically 90 amps when using 75°C-rated terminations, which is standard for most residential panels and subpanels. Always confirm the termination temperature rating and apply any required correction factors for ambient temperature or conductor bundling to ensure code compliance.

You should upsize from 2 AWG aluminum wire if your voltage drop calculation exceeds 3% for branch circuits or 5% for feeders plus branches. This often occurs in long runs over 100 feet or with higher current loads. In such cases, moving to 1/0 or 2/0 aluminum wire helps maintain performance and code compliance.

Yes, 2 AWG aluminum wire with USE-2 insulation is rated for direct burial and is commonly used for underground feeders to detached buildings. Always verify that the cable is marked for direct burial and meets local code requirements for burial depth and warning tape.

Key steps include cleaning the conductor with a non-abrasive brush, applying oxide-inhibiting compound, using only AL/CU or AL9CU-rated lugs, and torquing connections to the manufacturer's specification. Documenting torque values and performing thermal scans after energizing the circuit further ensure long-term safety.

2 AWG aluminum wire is lighter and generally less expensive than copper, making it ideal for long feeders or budget-sensitive projects. However, it has higher resistance, so voltage drop is greater for the same length and load. Aluminum also requires stricter termination practices and periodic inspection compared to copper.

Servicio en línea

Servicio en línea 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360