In today's fast-paced industrial and commercial environments, the demand for efficient and safe equipment is paramount. Enter the aluminum portable lift, a revolutionary tool that has become indispensable across various sectors. But what makes these lifts so crucial? Imagine needing to perform maintenance tasks at height or transport goods across different levels in a warehouse. Sounds complex? Not with an aluminum portable lift.

These lifts are celebrated for their lightweight and durable construction, primarily due to their aerospace-grade aluminum alloy composition. This material not only provides exceptional strength but also ensures the lift is easy to maneuver, making it ideal for tight spaces and frequent relocations. The benefits of using aluminum extend beyond just weight reduction; its natural corrosion resistance means these lifts are built to last, reducing maintenance costs and downtime.

The versatility of aluminum portable lifts makes them a staple in settings like factories, hotels, and theaters, where they assist in tasks ranging from machinery maintenance to electrical repairs. Their robust yet manageable design ensures safety without sacrificing functionality, offering a perfect balance for diverse applications.

Throughout this article, we will delve deeper into the key design considerations that enhance the performance of these lifts, explore the advantages of aluminum as a material, and highlight the broad spectrum of applications that benefit from this technology. We'll also examine the critical safety features that come standard with these lifts and discuss how regular maintenance can prolong their lifespan. By the end, you'll understand why investing in a quality aluminum portable lift is a smart choice for elevating both safety and productivity.

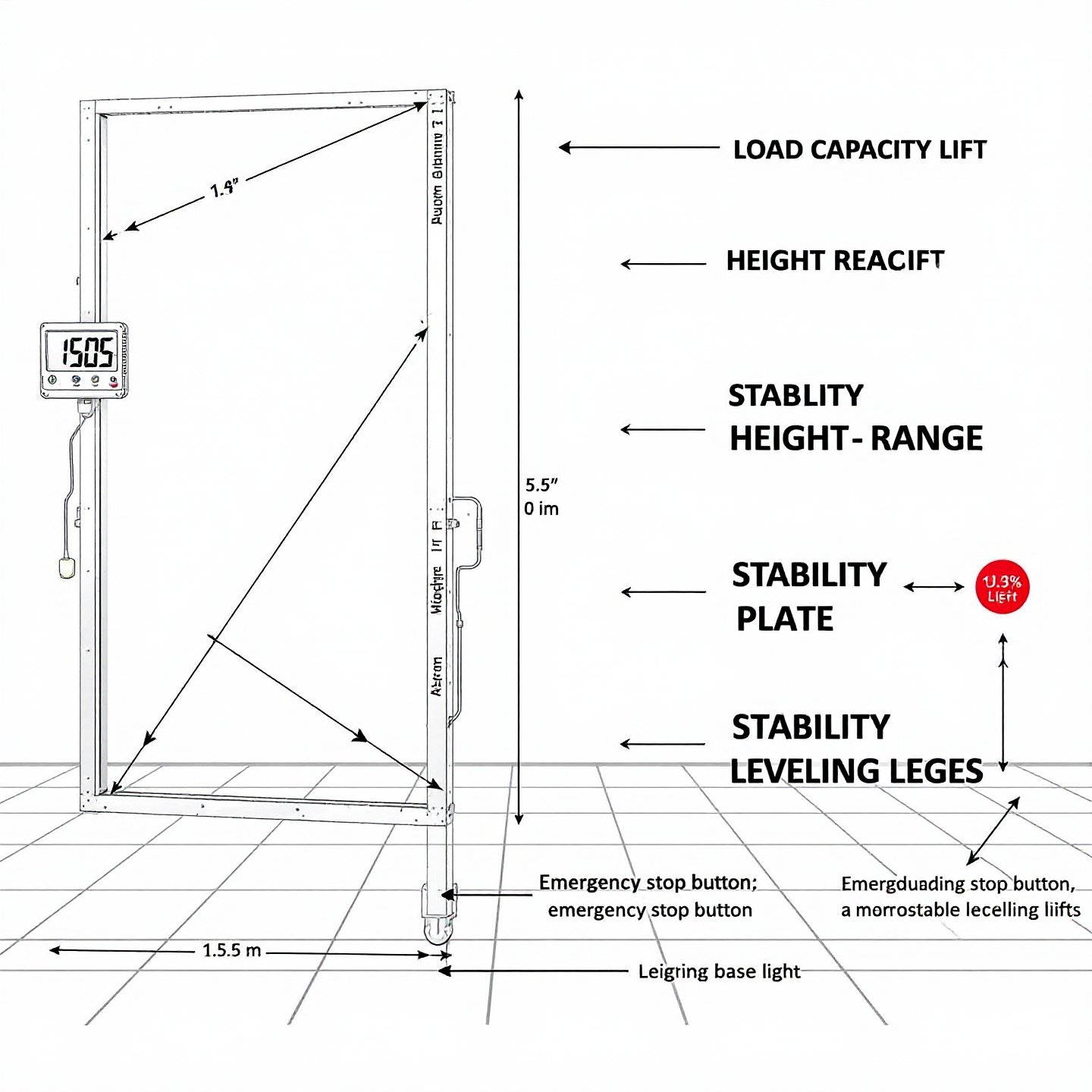

When it comes to designing aluminum portable lifts, several critical factors must be considered to ensure both safety and efficiency. One of the primary considerations is the load capacity . This determines the maximum weight the lift can safely handle, which is crucial for preventing overloading and potential accidents. Typically, the load capacity is influenced by the structural integrity of the aluminum used and the design of the lift itself.

Understanding the height range is equally important. The lift must reach the necessary heights for specific tasks without compromising stability. A well-designed lift will offer a balance between maximum height and load capacity, ensuring it can perform effectively in various scenarios.

Stability is another cornerstone of portable lift design. The use of outrigger systems and robust base designs are essential for maintaining balance, especially when the lift is extended to its full height. Outriggers, or stabilizers, extend from the base to provide additional support, preventing the lift from tipping over. These mechanisms are often adjustable, allowing the lift to be used on uneven surfaces while maintaining level stability.

The weight-to-strength ratio of aluminum plays a significant role in these design considerations. Aluminum's high strength relative to its weight means that the lifts can be both lightweight and robust, facilitating easy transport and setup without sacrificing safety. This characteristic is particularly valuable in environments where lifts need to be moved frequently.

Design choices directly impact user safety and operational efficiency. For instance, a lift with a well-engineered base and effective outriggers will provide a stable platform, reducing the risk of accidents during operation. Additionally, these features contribute to operational efficiency by minimizing setup time and ensuring the lift can be quickly adjusted to suit different working conditions.

In summary, the design of aluminum portable lifts must carefully balance load capacity, height range, and stability to ensure they meet the demands of various industrial and commercial applications. By focusing on these key design considerations, manufacturers can provide lifts that enhance both safety and productivity, making them invaluable tools in any work environment.

Choosing the right material for portable lifts is crucial, and aluminum stands out as the top choice for several compelling reasons. First, consider the weight reduction benefits. Aluminum's low density makes it significantly lighter than other metals like steel, facilitating easier handling and transportation. This characteristic is particularly advantageous in environments where mobility and ease of use are paramount.

Despite its lightweight nature, aluminum offers exceptional structural integrity . Its high strength-to-weight ratio ensures that aluminum portable lifts can withstand substantial loads while maintaining durability. This makes them ideal for repetitive use in demanding industrial and commercial settings. Moreover, aluminum naturally forms a protective oxide layer, enhancing its corrosion resistance and extending the lifespan of the lifts, even in harsh environments.

To further enhance durability, surface treatments such as anodizing are applied. This electrochemical process converts the aluminum surface into a corrosion-resistant oxide layer, providing an additional barrier against environmental damage and wear. Anodized aluminum profiles not only resist scratches and fading but also offer a sleek, metallic finish that enhances the lift's aesthetic appeal.

When selecting a manufacturer, Shengxin Aluminum emerges as a leader in producing high-quality, corrosion-resistant aluminum profiles. As a professional aluminum profile manufacturer, Shengxin offers advanced production techniques that ensure precision and performance. Their extensive range of production lines, including fusion casting and anodizing, guarantees that each profile meets the highest standards of quality and durability.

Shengxin's commitment to innovation and quality makes them a reliable partner for those seeking robust aluminum lift materials. Their expertise in producing eco-friendly and energy-saving profiles for various applications, from construction to transportation, underscores their ability to deliver customized solutions that meet specific industry needs.

In conclusion, selecting aluminum as the material for portable lifts provides a combination of lightweight handling, structural integrity, and longevity. By choosing a reputable manufacturer like Shengxin Aluminum, you can ensure that your lifts are built to withstand the demands of modern industrial and commercial environments, offering both safety and efficiency.

Aluminum portable lifts have revolutionized how industries approach tasks that require elevation, offering a versatile solution across a multitude of applications. Imagine a bustling warehouse where efficiency and safety are paramount. Here, a versatile aluminum lift becomes indispensable, seamlessly navigating through narrow aisles to facilitate the storage and retrieval of goods. Its compact design ensures that even the most confined spaces are accessible, maximizing operational efficiency.

In warehouse settings, these lifts are often used for high stacking and retrieval of inventory, reducing the physical strain on workers and minimizing the risk of accidents. Their lightweight yet robust construction allows for easy maneuverability, enabling quick deployment in dynamic environments where tasks and priorities can shift rapidly.

Beyond warehouses, aluminum portable lifts are a staple in facility maintenance. Whether it's changing light bulbs in a high-ceilinged atrium or performing routine inspections on HVAC systems, these lifts provide a stable and secure platform for workers. Their corrosion-resistant properties ensure reliability even in environments with fluctuating temperatures or high humidity levels.

Consider a shopping mall where aesthetics and functionality go hand in hand. Here, aluminum portable lifts are employed for tasks like installing decorations or performing maintenance on signage. Their sleek design and ease of operation make them the preferred choice in public spaces where minimal disruption is crucial.

In the construction industry, these lifts facilitate interior work such as painting and drywall installation, especially in areas that are difficult to access with traditional scaffolding. Their ability to be quickly set up and moved around the site enhances productivity and safety, ensuring projects stay on schedule.

Moreover, aluminum portable lifts are increasingly used in the power and telecommunications sectors. Their ability to handle outdoor conditions without succumbing to rust or degradation makes them ideal for maintaining power lines and communication towers.

In summary, the portable lift applications extend far beyond what traditional lifting equipment can offer. Their adaptability and ease of use make them a valuable asset in any industry that requires safe and efficient elevation solutions. As we explore further, the emphasis on safety features and compliance will underscore why these lifts are trusted across diverse sectors.

Ensuring safety while using aluminum portable lifts is paramount, and manufacturers have integrated a range of lift safety features to protect users. These features not only enhance operational safety but also comply with stringent industry standards, such as those set by OSHA and ANSI. Let's explore how these features contribute to a secure working environment.

Compliance with OSHA compliant lift standards is not just about meeting legal requirements; it's about fostering a culture of safety and trust. OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) provide comprehensive guidelines that ensure the safe design and operation of mobile elevating work platforms (MEWPs), including aluminum portable lifts.

For instance, ANSI A92 standards specify the inclusion of safety features like tilt sensors and load alarms, which are crucial for preventing accidents. Compliance with these standards means that the lifts are equipped to handle various operational scenarios safely, from uneven terrain to high-load conditions. This adherence to safety protocols reassures users and minimizes liability risks for businesses.

Furthermore, regular training and inspections are vital components of maintaining compliance. Operators must be trained to recognize and respond to potential hazards, while routine inspections ensure that all safety features are functioning correctly. This proactive approach not only enhances safety but also prolongs the lifespan of the equipment.

In conclusion, the integration of robust safety features and strict adherence to regulatory standards make aluminum portable lifts a reliable choice for any industry. As we move forward, exploring innovative accessories and customizations will further illustrate how these lifts can be tailored to meet specific operational needs.

When it comes to enhancing the functionality of aluminum portable lifts, the range of available lift accessories and customizations can make a significant difference in productivity and safety. These enhancements allow businesses to tailor their equipment to meet specific job requirements, ensuring that each lift is optimally configured for its intended use. But what exactly can these add-ons offer?

Imagine you're working in a busy warehouse where the ability to quickly adapt to various tasks is crucial. By incorporating accessories like fork extensions or boom assemblies, you can transform a standard lift into a versatile tool capable of handling diverse materials and reaching challenging areas. These accessories not only enhance the lift's capabilities but also improve operational efficiency by reducing the time needed to switch between tasks.

For those in construction or maintenance, accessories such as outrigger assemblies provide additional stability, ensuring safety when working on uneven surfaces. Meanwhile, aluminum trays can be used to organize tools and materials, keeping the workspace tidy and reducing the risk of accidents.

Customization goes beyond simple add-ons. With manufacturers like Shengxin Aluminum, you can explore customizable aluminum lift profiles that cater to specific operational needs. Whether it's adjusting the height, load capacity, or integrating advanced control systems, these customizations ensure that the lift aligns perfectly with your workflow.

Consider a scenario where precision is key, such as in a manufacturing environment. Here, integrating features like turntables or advanced control systems can significantly enhance productivity by allowing operators to maneuver materials with greater ease and accuracy. This level of customization not only boosts efficiency but also contributes to a safer work environment by reducing manual handling and associated risks.

| Accessory | Functionality | Impact on Productivity |

|---|---|---|

| Fork Extensions | Extend reach for handling larger loads | Increases load capacity and reduces handling time |

| Boom Assemblies | Enhance lift height and range | Improves access to high or hard-to-reach areas |

| Outrigger Assemblies | Provide additional stability on uneven surfaces | Enhances safety and operational confidence |

| Aluminum Trays | Organize tools and materials | Reduces clutter and improves workflow efficiency |

In conclusion, the potential to customize and accessorize aluminum portable lifts opens up numerous possibilities for enhancing their utility and efficiency. By choosing a manufacturer like Shengxin Aluminum, known for their high-quality, customizable profiles, businesses can ensure their lifts are perfectly suited to their operational demands. As we continue, understanding how regular maintenance can further extend the lifespan of these lifts will highlight the full spectrum of benefits they offer.

To ensure your aluminum portable lift remains in peak condition, implementing a thorough maintenance strategy is essential. Regular upkeep not only prolongs the lift's lifespan but also enhances safety and minimizes unexpected downtime, which can disrupt operations and inflate costs. But how can you effectively maintain your lift?

Conducting daily inspections is a cornerstone of effective maintenance. These checks help identify potential issues before they escalate into significant problems. Here are key items to include in your inspection checklist:

Beyond daily checks, adopting a preventive maintenance approach can significantly reduce repair costs and extend the lift's service life. Here’s how to implement this strategy effectively:

Regular maintenance offers numerous benefits, including reduced downtime, improved safety, and cost savings. By addressing minor issues promptly, you prevent them from developing into costly repairs, ensuring your lift remains operational and safe for use.

In conclusion, implementing a comprehensive maintenance plan for your aluminum portable lift is crucial for maximizing its lifespan and reliability. By following these lift maintenance tips , you can ensure that your lift continues to perform efficiently, enhancing productivity and safety in your work environment.

As we wrap up our exploration of aluminum portable lifts, it's clear that these innovative tools offer significant advantages across various industries. From their lightweight design and corrosion resistance to their versatile applications and robust safety features, aluminum lifts are a smart investment for any business looking to enhance efficiency and safety.

One of the key benefits of investing in an aluminum portable lift is its ability to adapt to diverse operational needs. Whether you're managing warehouse operations, conducting facility maintenance, or working in construction, these lifts provide a reliable and efficient solution for elevating tasks. Their ability to navigate tight spaces and handle frequent relocations makes them invaluable in dynamic work environments.

Moreover, choosing a reputable manufacturer like Shengxin Aluminum can further enhance the value of your investment. Known for their high-quality, corrosion-resistant profiles and advanced production techniques, Shengxin Aluminum ensures that each lift meets the highest standards of durability and performance. Their commitment to innovation and quality positions them as a leader in the industry, offering customized solutions that cater to specific operational demands.

By selecting a Shengxin Aluminum lift, you not only benefit from superior craftsmanship but also contribute to a safer, more productive work environment. Their extensive range of customizable options allows you to tailor the lift to your exact requirements, ensuring optimal performance and longevity.

In closing, the decision to invest in aluminum lift technology is a strategic move towards enhancing your operational capabilities. With the right choice of manufacturer, such as Shengxin Aluminum, you can rest assured that your investment will yield long-term benefits in terms of safety, productivity, and efficiency. Explore the possibilities with Shengxin today and elevate your business to new heights.

Aluminum portable lifts offer lightweight maneuverability, durability, and corrosion resistance, making them ideal for diverse applications in industrial and commercial settings. Their design ensures easy handling and transport, enhancing operational efficiency and safety.

These lifts incorporate safety features like guard rails, anti-slip platforms, and lockable castors. Compliance with OSHA and ANSI standards ensures they are equipped with sensors and alarms to prevent accidents, fostering a secure work environment.

Aluminum is favored for its high strength-to-weight ratio, corrosion resistance, and longevity. Its lightweight nature allows for easy transport and setup, while its durability ensures the lift can withstand substantial loads and harsh conditions over time.

Regular inspections, timely replacement of worn components, and adherence to preventive maintenance schedules are crucial. These practices help prolong the lift's lifespan, reduce downtime, and ensure safe and efficient operation.

Yes, manufacturers like Shengxin Aluminum offer customizable profiles and accessories, allowing lifts to be tailored to specific operational requirements. Options may include fork extensions, boom assemblies, and advanced control systems for enhanced functionality.

Servicio en línea

Servicio en línea 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360