When it comes to the question, "does aluminum rust?", the answer is not as straightforward as it might seem. Unlike iron or steel, aluminum does not rust in the traditional sense. This is a crucial distinction for anyone working with aluminum across various industries, from construction to automotive manufacturing. Aluminum is renowned for its corrosion resistance, making it an invaluable material for applications where durability and longevity are key.

Aluminum's unique ability to resist corrosion stems from its natural formation of a protective oxide layer when exposed to oxygen in the air. This layer acts as a barrier, preventing further oxidation and maintaining the integrity of the metal. This property is particularly significant when compared to other metals like iron, which form rust (iron oxide) that can flake away and weaken the material over time. Thus, understanding aluminum's resistance to rusting and its superior corrosion resistance is vital for engineers, architects, and manufacturers who rely on its strength and reliability in their projects.

The term 'rust' is often used interchangeably with 'corrosion,' but they are not the same. Rust specifically refers to the reddish-brown oxide that forms on iron and steel when they react with oxygen and moisture. This process, known as rusting, results in iron oxide, which can flake off and weaken the metal over time. In contrast, corrosion is a broader term that encompasses the degradation of any metal through chemical reactions with their environment.

Aluminum, unlike iron, does not rust because it does not contain iron. Instead, when aluminum is exposed to oxygen, it undergoes an oxidation process that forms a thin, protective layer of aluminum oxide on its surface. This layer acts as a shield, safeguarding the underlying metal from further degradation. This is a key distinction in the rust vs corrosion debate, as aluminum oxide is stable and adheres firmly to the metal, unlike the flaking rust that forms on iron.

This natural formation of an aluminum oxide layer is what gives aluminum its impressive corrosion resistance. The layer can regenerate if damaged, offering continuous protection. Therefore, while aluminum does not rust in the traditional sense, it does corrode through oxidation, resulting in a protective aluminum oxide layer that enhances its durability in various applications.

When you think about metals and their reactions to the elements, you might wonder, "What makes aluminum so special?" The answer lies in its self-healing, protective oxide film. Unlike iron, which forms red rust that flakes away, aluminum develops a thin layer of aluminum oxide that acts as a barrier against further corrosion.

This aluminum oxide layer is unique because it adheres tightly to the metal, effectively sealing it from environmental factors like moisture and oxygen. Imagine a shield that not only defends but also regenerates itself when scratched or damaged. This is precisely how aluminum's protective oxide film works, continuously renewing to maintain the metal's integrity and appearance.

In practical terms, this means that aluminum can withstand harsh conditions without degrading, making it an ideal choice for applications ranging from everyday household items to high-performance industrial components. For instance, Shengxin Aluminum's extruded profiles are renowned for their robust oxide layers, ensuring long-lasting performance and reliability in various settings.

Moreover, the aluminum oxide layer is not only protective but also enhances the aesthetic appeal of the metal, offering a sleek, modern finish. This combination of durability and beauty makes aluminum a versatile material in both functional and decorative applications.

In conclusion, the self-healing nature of the aluminum oxide layer is what sets aluminum apart from other metals, providing a level of corrosion resistance that is unmatched. This characteristic is particularly beneficial in environments where other metals might fail, highlighting aluminum's superiority in maintaining structural integrity and longevity.

When considering materials for outdoor use, aluminum often emerges as a top contender due to its remarkable resistance to environmental elements. But what exactly makes aluminum so adept at withstanding the challenges posed by weather changes, pollution, and humidity?

The secret lies in its natural ability to form a robust aluminum oxide layer that acts as a protective shield. This layer is crucial for aluminum's performance in outdoor applications, such as furniture and roofing materials. Unlike other metals that may corrode or degrade, aluminum's oxide layer is self-renewing, meaning it can heal itself if damaged, maintaining the metal's integrity over time.

In scenarios involving fluctuating weather conditions, aluminum's resistance to moisture and temperature variations is particularly beneficial. For instance, in humid climates, where metals like iron might succumb to rust, aluminum maintains its structural soundness. This makes it an excellent choice for outdoor furniture that needs to withstand both the scorching summer sun and heavy rainstorms.

Moreover, aluminum's ability to resist pollution-related corrosion adds another layer of durability. Urban environments, often laden with pollutants, can accelerate the corrosion process in many metals. However, aluminum's protective oxide layer effectively minimizes this risk, ensuring that structures like aluminum roofing remain intact and aesthetically pleasing for years.

In conclusion, the unique properties of aluminum make it an ideal material for various outdoor applications. Its self-healing oxide layer not only provides excellent weather resistance but also enhances the longevity and appearance of aluminum products, making it a smart investment for both residential and commercial outdoor projects.

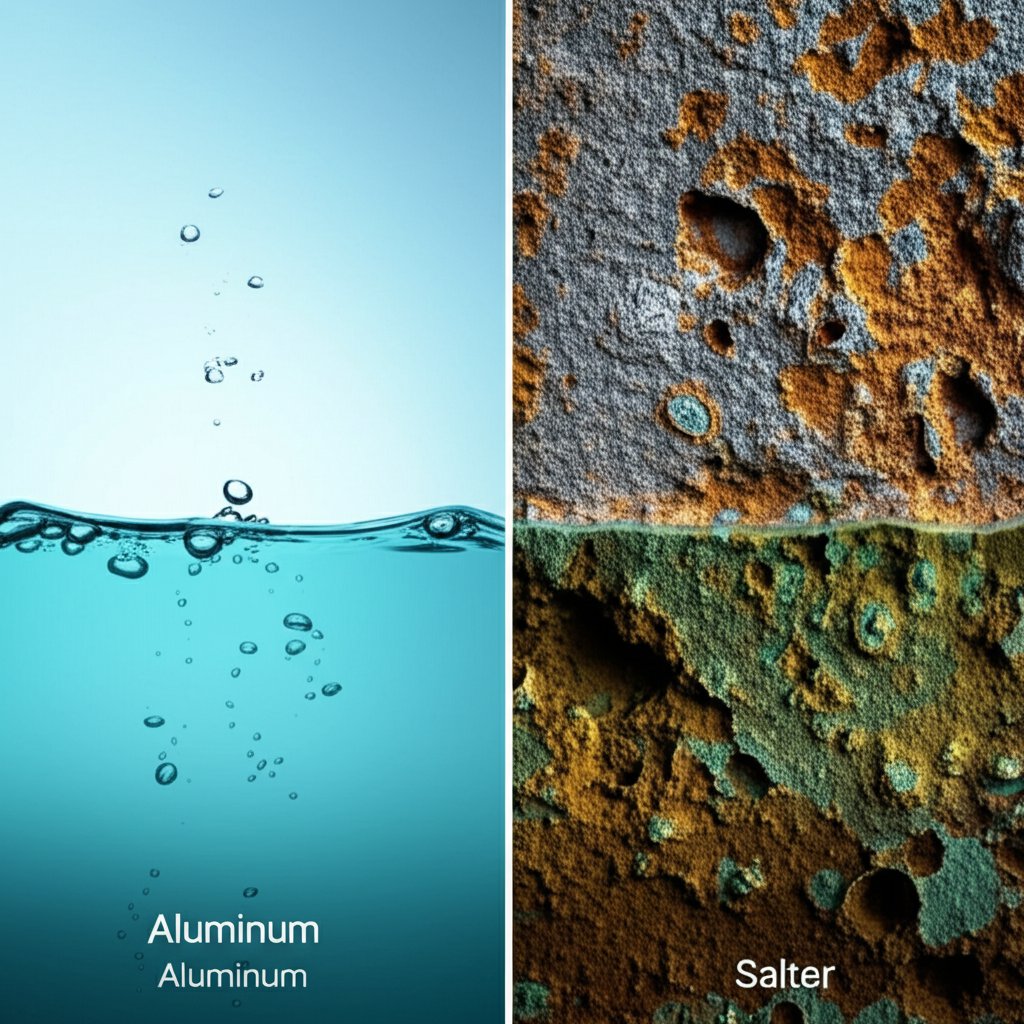

When it comes to understanding how aluminum interacts with water, it's essential to differentiate between freshwater and saltwater environments. You might wonder, "Does aluminum foil rust in water?" or "Does aluminum rust in saltwater?" The answers to these questions reveal much about aluminum's unique properties and its resilience in various aquatic settings.

In freshwater, aluminum exhibits remarkable stability. The protective oxide layer that naturally forms on its surface acts as a barrier, preventing further oxidation and maintaining the metal's integrity. This means that aluminum, including everyday items like aluminum foil, does not "rust" or degrade in the way that iron does. Instead, the thin layer of aluminum oxide provides continuous protection, ensuring the metal remains intact and functional.

However, the scenario changes when aluminum is exposed to saltwater. The presence of chloride ions in saltwater can lead to a specific type of corrosion known as pitting corrosion. These ions disrupt the protective oxide layer, creating small pits on the aluminum's surface. While these pits may not immediately compromise the structural strength of aluminum, they can affect its appearance and, over time, lead to more significant damage if not managed properly.

Despite this challenge, aluminum remains a popular choice for marine applications, thanks to its lightweight nature and resistance to general corrosion. The key to using aluminum effectively in saltwater environments lies in applying protective coatings, such as powder coatings, which enhance its durability by preventing chloride ions from reaching the metal surface. This approach ensures that aluminum products, from boats to seaside railings, can withstand the harsh conditions of saltwater while maintaining their functionality and aesthetic appeal.

In summary, while aluminum does not rust like iron, its behavior in water varies significantly between freshwater and saltwater. Understanding these differences is crucial for selecting the right protective measures to ensure aluminum's longevity and performance in aquatic environments.

When selecting aluminum for various applications, understanding the differences between cast aluminum and aluminum alloys is crucial for ensuring optimal performance and longevity. But what exactly sets these two apart in terms of corrosion resistance and durability?

Cast aluminum is typically formed by pouring molten aluminum into molds, resulting in products that are cost-effective and possess excellent casting characteristics. However, they often have a lower tensile strength and can be more susceptible to cast aluminum corrosion due to the presence of more alloying elements like silicon, which can promote localized corrosion. This makes them ideal for applications where complex shapes are needed but not necessarily high structural strength.

In contrast, wrought aluminum alloys, which are processed through mechanical working like rolling or extrusion, generally offer higher tensile strength and better resistance to external and internal defects. These alloys are often heat-treatable, enhancing their durability and making them suitable for demanding applications such as aerospace components and structural frameworks. The high aluminum alloy durability is attributed to the careful selection and balance of alloying elements, such as magnesium and copper, which improve strength and corrosion resistance.

For those seeking reliable aluminum solutions, Shengxin Aluminum offers a range of high-quality extruded profiles that leverage the advantages of both cast and wrought aluminum. Their products are designed to withstand harsh environments, ensuring longevity and performance. Shengxin's expertise in producing robust aluminum profiles, including those with enhanced oxide layers, provides an excellent option for industries requiring durable and corrosion-resistant materials.

In summary, while cast aluminum provides versatility in shape and cost, aluminum alloys excel in strength and corrosion resistance. Choosing the right type depends on the specific requirements of your project, and with Shengxin Aluminum's comprehensive offerings, you can find the perfect match for your needs.

When considering the durability of aluminum in challenging environments, you might ask, "How does anodizing improve aluminum's natural corrosion resistance?" The answer lies in the anodizing process itself, which transforms the metal's surface, offering enhanced protection and aesthetic benefits.

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, creating a robust protective barrier. During this process, aluminum is immersed in an electrolyte bath, typically sulfuric acid, and exposed to an electric current. This causes the surface to oxidize, forming a thick, controlled layer of aluminum oxide. According to Bonnell Aluminum, this layer is much harder than the naturally occurring oxide and offers a sapphire-like hardness.

The anodized layer is not only harder but also porous, allowing for the application of dyes to achieve various colors without compromising the metal's integrity. This makes anodized aluminum not only durable but also versatile in terms of design.

Anodized aluminum is particularly valued in industries where materials face extreme conditions. For instance, in the automotive sector, anodized components are used for their resistance to wear and corrosion, ensuring longevity and reliability. Similarly, in architectural applications, anodized aluminum is favored for its ability to withstand weathering while maintaining a sleek appearance.

The enhanced corrosion resistance of anodized aluminum is crucial in environments exposed to moisture and pollutants. The thick oxide layer acts as a barrier, preventing corrosive elements from reaching the underlying metal. This is why anodized aluminum is a popular choice for window frames, curtain walls, and other exterior architectural elements.

In conclusion, the anodizing process significantly enhances aluminum's natural properties, making it an ideal material for applications requiring both aesthetic appeal and high performance. By understanding the benefits of anodized aluminum, you can better appreciate its role in various industries, ensuring products that last longer and perform better in demanding conditions.

Keeping aluminum surfaces pristine involves more than just a quick wipe-down. To effectively maintain and clean aluminum, it's essential to understand the best practices that preserve its protective oxide layer. This layer is crucial for preventing further oxidation and ensuring the longevity of the metal.

Start by removing any loose dirt or debris from the aluminum surface. For routine cleaning, create a gentle solution using mild dish soap and warm water. Using a soft cloth or sponge, gently scrub the surface, paying attention to crevices where grime can accumulate. Rinse thoroughly with clean water to remove any soap residue.

For more stubborn stains, a paste made from baking soda and water can be effective. Apply the paste to the stained area and gently rub using a non-abrasive pad. This method is particularly useful for removing surface oxidation without scratching the metal.

If you notice white, chalky oxidation, a solution of equal parts white vinegar or lemon juice and water can be applied. The acidic nature of these solutions helps to dissolve aluminum oxide gently. Soak a soft cloth in the solution and rub the oxidized areas lightly. For smaller items, rubbing a slice of lemon directly onto the surface can also be effective.

After cleaning, consider applying an aluminum polish or wax to restore shine and add an extra layer of protection. Use a clean, soft cloth to apply the polish, following the product instructions for the best results. This step not only enhances the appearance but also helps to maintain the integrity of the oxide layer.

Remember, aluminum can scratch easily, so always use non-abrasive materials and avoid harsh chemicals that could damage the oxide layer. Regular maintenance using these techniques will ensure your aluminum surfaces remain in top condition.

Aluminum stands out among metals for its unique self-protective properties, which are crucial for its widespread use across various industries. Unlike iron, which succumbs to rust, aluminum forms a protective layer of aluminum oxide when exposed to the environment. This natural layer acts as a barrier against further oxidation, offering exceptional aluminum protection in diverse settings.

In different environments, aluminum exhibits remarkable resilience. For instance, in outdoor applications, its ability to resist weather-induced corrosion makes it a preferred material for structures like roofing and outdoor furniture. Similarly, in aquatic environments, while aluminum does not rust like iron, it can experience pitting corrosion in saltwater. However, with appropriate protective measures, such as coatings, aluminum maintains its structural integrity.

Proper care and maintenance are essential to enhance the longevity of aluminum products. Regular cleaning using non-abrasive methods preserves the oxide layer, ensuring continuous protection. Techniques like anodizing further strengthen this layer, making aluminum suitable for even the harshest conditions.

In conclusion, the difference between rust vs oxidation is pivotal to understanding aluminum's durability. While rust weakens metals like iron, aluminum's oxidation forms a protective shield that enhances its lifespan. This distinction underscores aluminum's superiority in applications where durability and resistance to environmental factors are paramount.

In answering the question, "does aluminum rust?", we've uncovered the unique properties that make aluminum an exceptional material choice. Unlike iron and steel, which succumb to rust, aluminum forms a protective aluminum oxide layer that shields it from further corrosion. This inherent aluminum corrosion resistance is what sets it apart, ensuring durability and longevity in a variety of applications.

As we've explored, aluminum's ability to resist degradation in both air and water environments makes it a versatile choice for industries ranging from construction to marine applications. Its self-healing oxide layer not only protects but also enhances the metal's aesthetic appeal, making it a reliable and attractive option for many projects.

For those seeking high-quality aluminum solutions, it's crucial to source materials from reputable suppliers. Companies like Shengxin Aluminum offer superior aluminum profiles known for their robust oxidation layers and exceptional performance. By choosing quality aluminum from trusted suppliers, you can ensure that your projects benefit from the full range of aluminum's protective properties.

In summary, while aluminum does not rust in the traditional sense, its remarkable resistance to corrosion makes it an invaluable material in both industrial and domestic settings. As you consider your next project, remember the advantages of aluminum and the importance of selecting quality materials from reliable suppliers to maximize performance and longevity.

Aluminum doesn't rust like iron because it lacks iron content. Instead, it forms a protective aluminum oxide layer that prevents further corrosion, ensuring its longevity.

Aluminum won't rust when wet, but it can corrode. Its protective oxide layer generally prevents damage, but in saltwater, chloride ions can cause pitting.

Aluminum is considered rust-proof due to its protective oxide layer. Other corrosion-resistant metals include stainless steel, copper, and brass.

Aluminum is lighter and more cost-effective, while stainless steel is more durable and heat-resistant. Both are corrosion-resistant but serve different purposes.

In saltwater, aluminum can experience pitting corrosion due to chloride ions, but protective coatings can enhance its resistance.

Servicio en línea

Servicio en línea 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360