Have you ever wondered what makes skyscraper window frames so sleek, or how lightweight vehicles and durable electronics come together? More often than not, the answer is extruded aluminum. This material quietly powers countless innovations around us, thanks to its unique blend of strength, flexibility, and sustainability.

So, what exactly is extruded aluminum? Imagine squeezing clay through a mold to create long, uniform pieces—except here, heated aluminum is forced through a specially shaped die. The result is a profile with a consistent cross-section, whether it’s a simple rod or a complex multi-chambered frame. This process unlocks remarkable design freedom, enabling engineers and designers to create everything from robust structural beams to intricate electronic enclosures.

Why has extruded aluminum become so essential across industries? Here’s what sets it apart:

If you’re curious to dive deeper into how this process works and why it’s shaping the future of engineering, check out this comprehensive guide: What Is Extruded Aluminum? Your Definitive Guide to Uses & Benefits.

As we explore the world of extruded aluminum, you’ll discover how this adaptable material is transforming industries—one profile at a time.

Ever picked up a window frame or a bike part and wondered how such complex shapes stay so light and strong? If you’ve asked, “What is extruded aluminum and why is it everywhere?”—you’re not alone. Let’s break it down in simple terms, then explore why this material is prized in modern engineering and design.

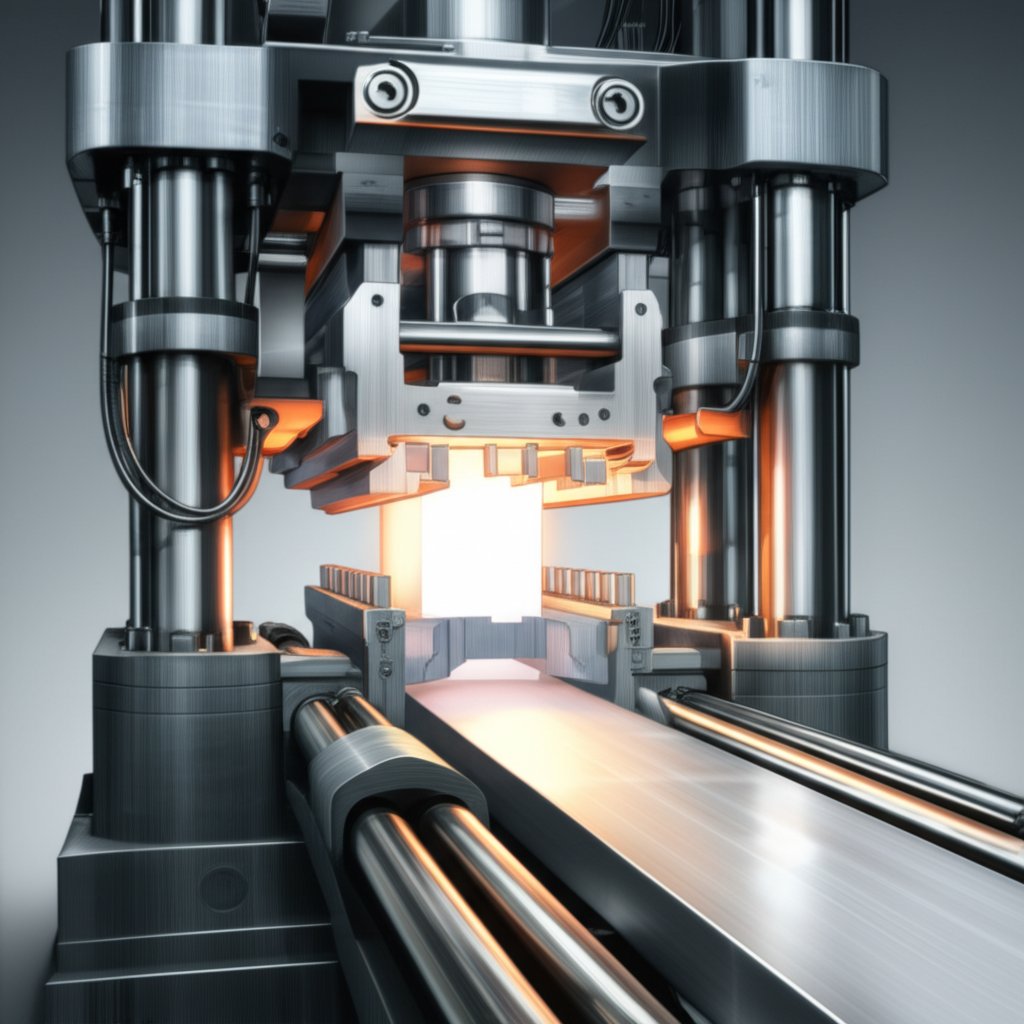

Imagine squeezing playdough through a shaped mold to make a long, uniform piece. Extruded aluminum is made in a similar way: a heated aluminum alloy (the billet) is pushed—or extruded—through a specially designed die. The opening of the die determines the profile’s final shape, whether it’s a simple rod, a hollow tube, or a complex multi-chambered frame.

This process creates lengths of aluminum with a consistent cross-sectional profile. These profiles can be cut, finished, and further fabricated to suit countless applications, from architectural structures to electronic enclosures (Eagle Aluminum).

The journey begins with bauxite ore, which is refined into pure aluminum. This metal is then alloyed for strength and formed into billets. These billets are heated until soft and malleable, then loaded into an extrusion press. With tremendous force, the press pushes the billet through a die, shaping the aluminum into a continuous profile. After extrusion, the profile is cooled, stretched for straightness, and cut to length. Additional steps like heat treating or surface finishing may follow to enhance strength or appearance (IQS Directory).

What makes this material so popular? It’s all about a unique combination of physical and chemical properties:

With these advantages, it’s easy to see why extruded aluminum is the go-to material for everything from skyscraper facades to high-speed trains. Its unique production method and beneficial properties make it a cornerstone of modern design and engineering. Next, we’ll take a closer look at the step-by-step process behind aluminum extrusion, revealing how raw material transforms into the versatile profiles that shape our world.

Ever wondered how that sleek window frame or sturdy machine rail is made? The secret lies in a precise, multi-step process known as aluminum extrusion. It might sound complex, but once you break it down, you’ll see how the aluminum extruder transforms raw material into the shapes that power modern engineering. Let’s walk through each stage, so you can understand exactly how an aluminum extrude becomes the finished product you see in everyday life.

Imagine shaping dough through a cookie press, but on an industrial scale—using intense heat, pressure, and engineering expertise. Here’s how the process unfolds:

For a clearer picture, here’s a simplified process flow diagram you might see in a manufacturing setting:

Die Preheating → Billet Preheating → Loading → Compression/Extrusion → Quenching → Shearing → Stretching → Cutting → Heat Treatment → Surface Finishing

The aluminum extruder—the machine at the heart of this process—applies the immense force needed to push the billet through the die. Its precision and control determine the quality, consistency, and complexity of the aluminum extruded profiles produced. Modern extruders can create everything from simple rods to intricate, multi-chambered shapes for specialized engineering needs (Atieuno).

Understanding this process helps you appreciate the engineering behind every aluminum extruded profile—whether it’s a structural beam, a window frame, or a precision electronics enclosure. Next, we’ll explore the variety of shapes and profiles this process makes possible, and how choosing the right one can elevate your project’s performance and design.

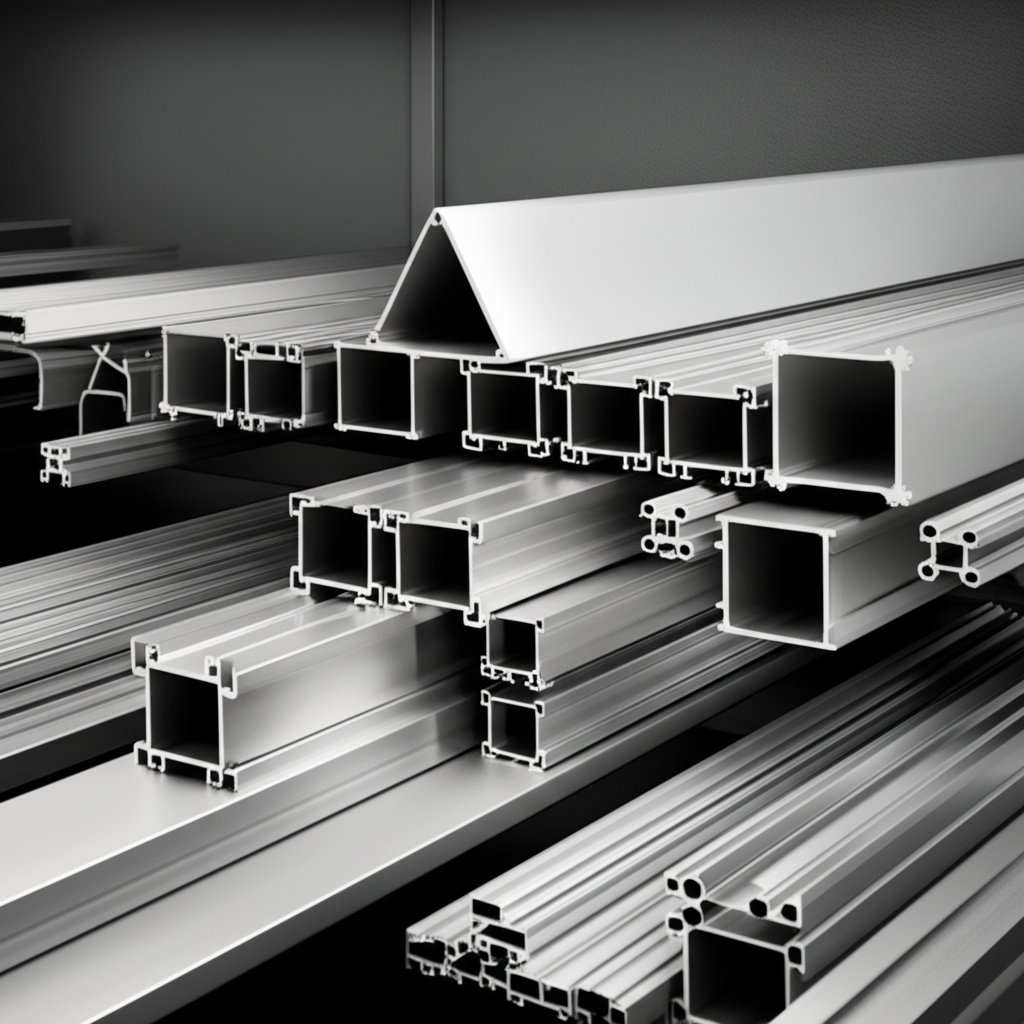

When you walk into a modern building, step onto a train, or assemble modular shelving, you’re likely interacting with extruded aluminum profiles—but have you ever wondered just how many shapes and sizes are out there? The answer: far more than you might expect! Let’s break down the essential aluminum extruded shapes you’ll encounter, and how they’re tailored to fit everything from architectural masterpieces to precision machinery.

Standard profiles are the backbone of the extrusion world. Manufacturers keep these shapes in stock, ready for quick delivery and easy integration into a wide range of applications. Wondering what these look like? Here’s a snapshot of the most common forms you’ll find (Wellste):

Sometimes, off-the-shelf just won’t cut it. That’s where custom profiles come in—engineered to meet unique performance, assembly, or design needs. Imagine intricate multi-chamber window frames for energy efficiency, or proprietary channels for a new piece of industrial equipment. Customization goes beyond shape; you can specify alloy, wall thickness, tolerances, and even surface finish (like anodizing or powder coating) to ensure the profile stands up to its intended environment (Wellste).

Leading manufacturers like Shengxin Aluminum offer extensive catalogs of both standard and custom extrusions. Thanks to advanced extrusion lines—ranging from small, precise dies to massive presses for structural beams—they can produce everything from architectural trims to robust industrial components, supporting projects in construction, transportation, and beyond.

From standard extruded aluminum channel to specialized extruded tubing aluminum or custom profiles, the options are nearly limitless. As you plan your next project, consider how the right profile can simplify construction, enhance durability, or unlock new design possibilities. Up next, we’ll dive into a profile that’s revolutionized modular assembly: the T-slot—showing how it brings flexibility and speed to custom builds.

Ever tried to build a custom workstation or machine frame and wished you could change the layout as your needs evolve? That’s where extruded aluminum t slot profiles shine. Imagine having a construction kit for adults—one that’s lightweight, strong, and endlessly adaptable. But what exactly is a T-slot, and why has it become the go-to solution for modular assembly in industries and workshops around the world?

At its core, a t slot extruded aluminum profile is a length of aluminum with T-shaped grooves (slots) running along one or more sides. These slots act like built-in tracks, allowing you to slide in specialized connectors, fasteners, or accessories at any point along the profile. Unlike traditional welded frames, you can assemble, adjust, or even completely reconfigure your structure—often with just basic hand tools and no permanent joins.

Profiles come in various shapes and slot configurations. Some have a single slot, while others feature multiple slots on all sides, offering even greater design flexibility. Sizes are standardized within certain series (like 10, 15, 30, or 40 series), making it easy to find compatible hardware and accessories (Parco, Inc.).

Wondering what sets extruded t slot aluminum apart from other framing materials? Here are the top advantages:

The adaptability of T-slot extrusions means you’ll spot them in countless settings. Here are some of the most popular applications:

In short, T-slot extruded aluminum isn’t just a building material—it’s a platform for innovation. By combining strength, flexibility, and ease of use, these profiles empower anyone to design, build, and adapt structures as needs change. Next, we’ll explore how standardized modular systems like 80/20 take this concept even further, enabling rapid prototyping and custom solutions for every industry.

Ever wished your next project could snap together like building blocks—no welding, no hassle, and endless room for changes? That’s exactly the promise behind 80 20 extruded aluminum and similar modular T-slot systems. But what does “80/20” really mean, and why are these systems the gold standard for rapid prototyping, industrial frameworks, and creative DIY builds?

Imagine a set of aluminum profiles engineered with T-shaped slots running along their length. These slots are precisely sized to accept a wide range of standardized fasteners, brackets, and accessories. The term 80/20 refers to a popular brand and system of these modular T-slot extrusions, but it’s also become shorthand for the concept itself—much like “Kleenex” for tissues. You’ll also see it written as 8020 extruded aluminum in technical catalogs and forums.

So, what makes 80/20 stand out? The answer is its strict adherence to standardized sizing and slot geometry. Whether you choose a 10 Series (1" x 1" profile), a heavier-duty 15 Series (1.5" x 1.5"), or metric equivalents, you’re guaranteed compatibility with a massive ecosystem of connectors, panels, hinges, wheels, and more (RMMC). This means you can mix and match parts with confidence—no custom machining required.

While 80/20 is the most recognized name, several other manufacturers offer similar modular T-slot systems—often with nearly identical slot dimensions and accessory compatibility. The core idea remains the same: standardized profiles, universal slots, and a shared ecosystem of hardware. Some systems, like Bosch Rexroth, offer metric sizes or heavier-duty profiles for industrial loads, while others cater to hobbyists or specialized automation needs.

V-Slot profiles are another alternative, featuring a V-shaped groove for linear motion applications (think 3D printers and CNC machines). However, for structural framing and static assemblies, T-slot systems like 80/20 remain the top choice due to their robust connection methods and broader accessory range (PTSMAKE).

In essence, 80/20 and similar extruded aluminum T-slot systems empower you to design, build, and refine solutions quickly—whether you’re prototyping a new machine, setting up a lab, or crafting a custom workstation. Next, let’s see how these modular frameworks translate into real-world applications across architecture, industry, and beyond.

Ever wondered how the same material can frame a skyscraper’s window, shield sensitive electronics, and support the chassis of a high-speed train? That’s the power of extruded aluminum framing. Its unique blend of strength, lightness, and adaptability means it’s found almost everywhere—often in places you wouldn’t expect. Let’s break down the most common and impactful uses, so you can see firsthand how versatile this material truly is.

Manufacturers like Shengxin Aluminum have played a pivotal role in advancing these applications. Their extensive production capabilities and deep expertise enable the delivery of high-quality extrusions for demanding sectors, from rail transit to renewable energy. When you see a sleek enclosure, a sturdy rail, or a cutting-edge solar frame, chances are it’s made possible by innovative extruded aluminum framing. Next, we’ll explore how to get custom extrusions made for your unique project requirements.

Ever looked at a product and thought, “I wish there was an aluminum profile that fit exactly what I need?” That’s where custom aluminum extruders come into play. Whether you’re designing for aerospace, rail transit, or a one-of-a-kind architectural project, custom extrusions unlock possibilities that standard profiles simply can’t match. But how do you turn a sketch—or even just an idea—into a finished, high-performance aluminum component? Let’s walk through the process step by step, so you can confidently approach your next custom extrusion project.

Standard profiles are great for many jobs, but sometimes your requirements are too unique for off-the-shelf solutions. You might need:

If any of these sound familiar, custom aluminum extruders are your best route.

Sounds complex? It’s actually a well-defined journey that takes you from concept to finished part. Here’s what you can expect:

| Step | What Happens | Key Considerations |

|---|---|---|

| 1. Design & CAD Modeling | Your idea is transformed into a precise digital drawing (CAD). This model defines every detail of the profile’s cross-section. | Collaborate closely with your extruder’s engineers for manufacturability and cost savings (Gabrian). |

| 2. Die Design & Manufacturing | A custom steel die (the mold) is created to match your CAD profile. This is a one-time investment for your unique shape. | More complex shapes may require multi-part dies, increasing tooling costs (ADM). |

| 3. Alloy Selection | Choose the aluminum alloy that best fits your performance needs—strength, corrosion resistance, machinability, or appearance. | Common choices: 6061 for strength and machinability, 6063 for decorative or architectural use, 7075 for high-strength needs. |

| 4. Tolerance & Specification Setting | Define the dimensional tolerances your part must meet. Tighter tolerances increase production complexity and cost. | Balance between precision and budget—consult with your extruder for best practices. |

| 5. Surface Finishing | Decide on finishes: anodizing for corrosion resistance, powder coating for color, or mechanical/chemical treatments for special properties. | Finishes can enhance both durability and appearance (Gabrian). |

| 6. Minimum Order Quantities (MOQs) | Most custom extrusions require a minimum order, since the setup costs are significant for small runs. | Discuss MOQs with your supplier early to align expectations. |

| 7. Tooling & Production Costs | Tooling (die-making) is a one-time fee; per-part costs depend on profile complexity, material, and quantity. | Request a detailed quote up front to avoid surprises (ADM). |

Choosing the right extrusion partner can make or break your project. Leading manufacturers like Shengxin Aluminum offer a full suite of services: from expert engineering support and advanced die-making to high-capacity production lines and rigorous quality assurance. Their track record includes supplying custom extrusions for demanding sectors such as rail transit and new energy vehicles—where performance, precision, and reliability are non-negotiable.

With over 100 production lines, including specialized equipment for deep processing and large-scale extrusion, Shengxin Aluminum is equipped to handle everything from intricate architectural trims to heavy-duty structural components. Their experience collaborating on metro lines and high-tech industrial projects means you’ll benefit from industry-leading expertise and a commitment to quality at every step.

Ready to bring your vision to life? By working with skilled custom aluminum extruders, you gain a partner who translates your ideas into tangible, high-performance profiles—opening new doors for design, innovation, and efficiency. In the next section, we’ll look at how to source extruded aluminum, whether for custom projects or standard stock, so you can move seamlessly from design to delivery.

Need extruded aluminum for your next project and wondering, “Where can I find extruded aluminum near me?” Or maybe you’re searching for specific sizes—like where to buy 8 foot lengths of extruded aluminum—but aren’t sure which source offers the best deal, fastest delivery, or most customization. Let’s break down your sourcing options, practical tips, and how current market trends, including extruded aluminum scrap price, can impact your decision.

With so many suppliers out there, picking the right one can feel overwhelming. Start by asking yourself: Do you need a standard profile quickly, or a custom solution for a unique build? Are you buying a handful of pieces, or placing a bulk order for manufacturing?

Here are the main ways to source extruded aluminum:

| Sourcing Option | Best For | Quantity | Customization | Price | Lead Time |

|---|---|---|---|---|---|

| Local Distributor | Immediate pickup, small jobs, rapid prototyping | 1–50 pcs | Limited (stock only) | $$ | Same day–1 week |

| Online Retailer | Convenience, variety, remote orders | 1–100 pcs | Limited (standard profiles) | $$–$$$ (plus shipping) | 2–7 days |

| Manufacturer Direct | Bulk orders, custom profiles, special alloys/finishes | 100+ pcs | Extensive (custom shapes, finishes, cut-to-length) | $–$$ (best for volume) | 2–8 weeks (custom) |

What about recycling or buying scrap for cost savings? The extruded aluminum scrap price fluctuates based on global market dynamics, LME (London Metal Exchange) prices, and regional supply and demand. In recent quarters, scrap prices have faced downward pressure due to increased supply, subdued demand from sectors like automotive, and volatile primary aluminum prices (Procurement Resource). If you’re considering using recycled material for non-structural applications, keep in mind that prices may continue to trend lower, but availability and quality can vary by region and grade.

Ultimately, the best sourcing route depends on your project’s size, speed, and customization needs. For large or specialized orders, working with a high-capacity manufacturer like Shengxin Aluminum ensures you get quality, flexibility, and expert support from design to delivery. Ready to take the next step? In our final section, we’ll recap the essential advantages of extruded aluminum and offer guidance for choosing the right partner for your next build.

When you look around—at the skyline of a city, the frame of a high-speed train, or the sleek enclosure of your favorite device—you’ll notice one material quietly powering progress: extruded aluminum. But what makes it so indispensable, and why is it chosen time and again for projects that demand performance, flexibility, and sustainability?

Let’s recap the standout qualities that have made extruded aluminum a cornerstone of modern design and engineering:

From architecture and transportation to electronics and renewable energy, extruded aluminum continues to unlock new possibilities. Advances in extrusion technology, alloy development, and surface finishing mean that today’s solutions are stronger, lighter, and more adaptable than ever. Whether you’re designing for extreme climates, tight tolerances, or rapid assembly, this material delivers—time after time.

Imagine what you could build if you had a partner who not only understood the science behind extruded aluminum but also offered the scale and expertise to bring your vision to life. That’s where manufacturers like Shengxin Aluminum come in. With advanced production lines, deep industry experience, and a commitment to quality, Shengxin supports projects ranging from rail transit to cutting-edge industrial designs—ensuring your next build benefits from the very best this remarkable material has to offer.

So, as you plan your next innovation—whether it’s a new product, infrastructure, or creative endeavor—consider the enduring advantages of extruded aluminum. The possibilities are as limitless as your imagination.

Extruded aluminum refers to aluminum alloy that has been forced through a specially shaped die to create a continuous profile with a specific cross-section. This process results in strong, lightweight components used across industries for their durability, corrosion resistance, and design versatility.

Extruded aluminum offers improved strength and durability compared to rolled or cast forms, thanks to its unique structure and the ability to concentrate material where needed. It also allows for complex shapes, better corrosion resistance, and easier assembly in modular designs.

Extruded aluminum is widely used in architecture (windows, curtain walls), industrial automation (machine frames, enclosures), transportation (vehicle chassis, rail systems), electronics (heat sinks, cases), renewable energy (solar frames), and consumer products due to its versatility and strength.

You can source extruded aluminum from local distributors for small quantities, online retailers for variety and convenience, or direct from manufacturers for bulk orders and custom profiles. Consider factors like quantity, profile type, finish, and lead time when choosing a supplier.

Shengxin Aluminum stands out for its extensive production capabilities, advanced extrusion lines, and expertise in custom solutions. With a strong track record in sectors like rail transit and new energy, Shengxin provides high-quality profiles and comprehensive support from design to delivery.

Servicio en línea

Servicio en línea 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360