Aluminum tubing's diverse applications in construction, automotive, and aerospace (AI-generated)

Aluminum tubing is a cornerstone material in many industries due to its exceptional properties and adaptability. From the towering skyscrapers in construction to the lightweight components in aerospace, aluminum tubing plays a crucial role in modern engineering and design. But what makes it so indispensable across these diverse fields? Let's delve into the key reasons for its widespread usage.

First and foremost, the lightweight nature of aluminum tubing makes it an excellent choice for applications where weight is a critical factor. In the automotive industry, for instance, reducing vehicle weight can significantly enhance fuel efficiency and performance. Similarly, in aerospace, every pound saved can lead to substantial cost savings and improved flight dynamics.

Another compelling attribute of aluminum tubing is its corrosion resistance. This property ensures longevity and reliability, especially in environments exposed to moisture or harsh weather conditions. This makes aluminum tubing a preferred material for outdoor structures and marine applications, where resistance to rust and degradation is paramount.

Moreover, aluminum tubing is renowned for its durability. Despite being lightweight, it offers remarkable strength and can withstand significant stress, making it suitable for structural applications. For projects requiring enhanced durability and aesthetic flexibility, pre powdercoated aluminum square tubing is an excellent choice. This balance of strength and weight is particularly beneficial in construction, where materials must support substantial loads without adding unnecessary weight.

In addition to these physical properties, aluminum tubing is also appreciated for its versatility. It can be easily extruded, molded, and shaped into various forms, accommodating a wide range of design specifications and functional requirements. This adaptability is why aluminum tubing is extensively used in sectors like furniture design, where both aesthetic and functional customization are essential.

In conclusion, the combination of lightweight, corrosion resistance, and durability makes aluminum tubing a versatile choice for numerous applications. Whether in the automotive, aerospace, or construction industries, its benefits are clear and compelling. As we continue to innovate and develop new technologies, the role of aluminum tubing is set to expand even further, solidifying its position as a material of choice in the modern world.

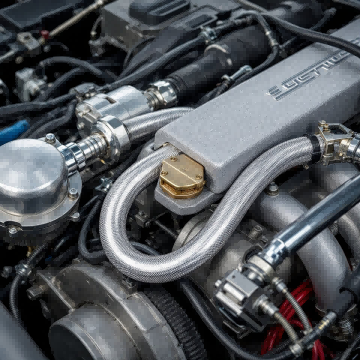

1/2 OD aluminum tubing used as a fuel line in automotive systems (AI-generated)

When it comes to automotive fuel systems, the choice of materials can significantly affect performance and durability. One popular option is the 1/2 OD aluminum tubing, particularly favored for its role as a hard fuel line. But why is this specific type of tubing so well-suited for automotive applications?

First, let's consider the lightweight nature of aluminum. In the automotive industry, every ounce counts. Reducing the weight of components like fuel lines can lead to improved fuel efficiency and overall vehicle performance. The lightweight property of aluminum tubing allows for easier handling and installation, making it a practical choice for both manufacturers and mechanics.

Moreover, corrosion resistance is another critical factor. Aluminum naturally forms a protective oxide layer that prevents further oxidation, making it resistant to the corrosive effects of modern fuels, which often contain ethanol and other additives. This resistance ensures that the fuel lines remain intact and functional over time, reducing the need for frequent replacements and maintenance.

In addition to these benefits, aluminum tubing is known for its flexibility and ease of fabrication. It can be bent and shaped to fit the specific contours of a vehicle's design without compromising its structural integrity. This flexibility is particularly advantageous in custom automotive builds, where precise fitting is crucial.

· Compatibility with AN fittings: Aluminum tubing is compatible with AN (Army-Navy) fittings, which are widely used in automotive applications for their reliability and ease of installation. These fittings are designed specifically for aluminum tubing, ensuring a secure and leak-proof connection.

· Cost-effectiveness: Compared to other materials like stainless steel, aluminum is more affordable, making it an economical choice for both hobbyists and professional mechanics.

· Durability under heat: Aluminum's ability to withstand high temperatures without degrading makes it suitable for use in environments where heat dissipation is essential, such as near engine components.

In summary, the 1/2 OD aluminum tubing is an excellent choice for automotive fuel lines due to its lightweight, corrosion-resistant, and flexible nature. These characteristics ensure that it meets the demanding requirements of modern vehicles, providing a reliable and efficient solution for fuel delivery systems. As automotive technology continues to evolve, the role of aluminum tubing remains pivotal, offering a blend of practicality and performance that few materials can match. For a foundational understanding of aluminum tubing's versatility and general applications, visit our detailed article on aluminum tubing.

Imagine a construction project where both durability and visual appeal are paramount. This is where powdercoated aluminum tubing steps into the spotlight. Pre-powdercoated aluminum square tubing offers a unique blend of strength, longevity, and aesthetic versatility, making it a favored choice in modern construction and design projects. Its robust protective coating further distinguishes it from other aluminum tubing options, emphasizing the advantages of pre powdercoated aluminum square tubing in both structural and decorative applications.

Powder coating is a finish that involves applying a dry powder to the surface of aluminum, which is then cured under heat to form a solid, protective layer. This process not only enhances the durability of the aluminum but also contributes significantly to its aesthetic appeal. With a wide range of colors and finishes available, powdercoated aluminum tubing can be tailored to meet specific design requirements, whether you're aiming for a sleek, modern look or a more traditional style.

· Enhanced Durability: The powder coating adds a robust layer of protection against environmental factors like UV rays, moisture, and chemical exposure, which can lead to corrosion. This makes it an ideal choice for outdoor applications, where materials are constantly exposed to the elements.

· Aesthetic Flexibility: With an extensive palette of colors and finishes available, powdercoated aluminum tubing can be customized to complement any architectural style or design vision. Whether it's a vibrant hue or a subtle matte finish, the possibilities are virtually endless.

· Low Maintenance: The smooth, hard finish of powdercoated surfaces makes them easy to clean and resistant to scratching and chipping. This reduces the need for frequent maintenance, saving time and resources in the long run.

When selecting pre-powdercoated materials, there are several considerations to keep in mind. First, the choice of alloy is crucial. Different alloys offer varying levels of strength and flexibility, so it's important to choose one that aligns with the specific requirements of your project. Additionally, the thickness of the coating should be considered, as it affects both the durability and the final appearance of the tubing.

In conclusion, pre-powdercoated aluminum square tubing offers a compelling combination of durability, aesthetic appeal, and low maintenance, making it a valuable asset in construction and design projects. As you plan your next project, consider how this versatile material can enhance both the functionality and the visual impact of your designs. With its myriad benefits, powdercoated aluminum tubing is not just a practical choice—it's a strategic one.

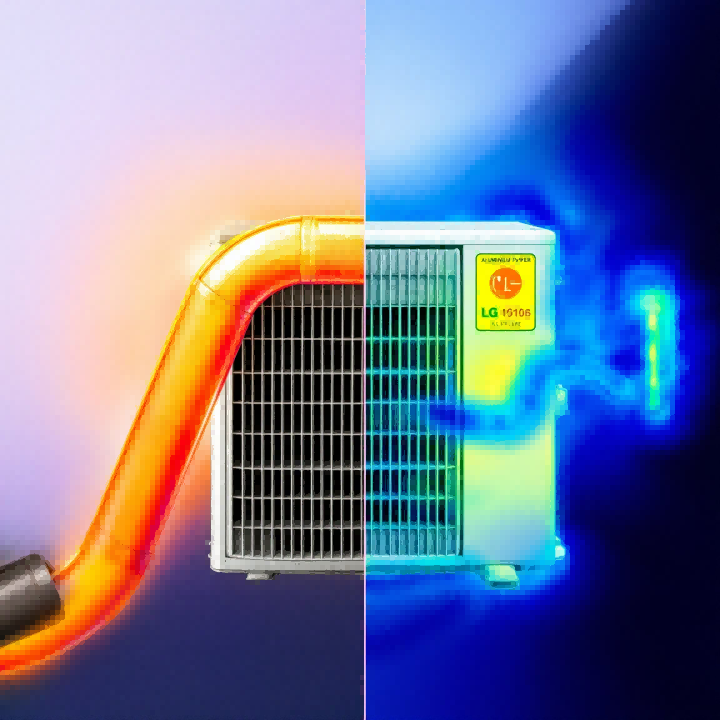

Comparison of copper and aluminum tubing in LG air conditioners (AI-generated)

When it comes to the internal components of LG window air conditioners, the choice between copper and aluminum tubing is pivotal. Both materials serve the critical function of heat exchange, but they come with distinct properties that influence performance, cost, and durability. Let’s explore why manufacturers might choose one over the other and what implications these choices have for the consumer.

One of the primary considerations in selecting tubing material for air conditioners is thermal conductivity. Copper is known for its superior thermal conductivity, approximately 60% higher than that of aluminum. This means copper can transfer heat more efficiently, which is crucial for the rapid cooling required in air conditioning systems. However, the performance advantage of copper must be balanced against other factors.

Despite its thermal advantages, copper is significantly more expensive than aluminum, often costing about three times as much. This cost difference can be a decisive factor, especially in budget-friendly models. Furthermore, copper is denser and heavier, which can increase the overall weight of the air conditioning unit. Aluminum, being lighter, offers substantial weight savings, making it easier to install and handle, particularly in larger units.

Durability is another critical factor. Copper is generally more durable and less prone to physical damage than aluminum. However, aluminum has a natural corrosion resistance due to its oxide layer, which can be advantageous in humid environments where corrosion is a concern. This resistance to corrosion can translate to a longer lifespan for aluminum components in certain settings.

In conclusion, the choice between copper and aluminum tubing in LG air conditioners involves a trade-off between thermal efficiency, cost, weight, and durability. While copper offers superior heat transfer capabilities, aluminum provides a more economical and lightweight alternative. Understanding these differences can help consumers make informed decisions based on their specific needs and the environmental conditions in which the air conditioner will operate.

When considering materials for various applications, 1/2 inch aluminum tubing stands out for its versatility and efficiency. This tubing size is commonly used across multiple industries due to its balanced properties, making it a practical choice for projects requiring both strength and flexibility.

One of the most popular grades for this tubing is 6061-T6, renowned for its excellent mechanical properties. The 1/2 inch outer diameter (OD) tubing typically features a wall thickness of around 0.120 inches, providing a robust yet lightweight solution. This specification ensures that the tubing can handle substantial pressure without adding unnecessary weight, a crucial factor in many engineering applications.

Moreover, the 6061 aluminum alloy used in these tubes provides a high strength-to-weight ratio, making it suitable for both structural and non-structural uses. Its corrosion resistance is enhanced by the natural formation of an oxide layer, which protects against environmental degradation.

Given its specifications, 1/2 inch aluminum tubing is widely used in plumbing systems, where its corrosion resistance ensures longevity and minimal maintenance. Its ability to withstand pressure makes it ideal for transporting fluids and gases without risk of leaks or bursts.

In the HVAC industry, this tubing is often employed in systems requiring efficient heat exchange. The lightweight nature of aluminum allows for easy installation and handling, which is particularly beneficial in large-scale projects where labor costs can be significant.

Structurally, 1/2 inch aluminum tubing is frequently used in frameworks and supports. Its strength and lightweight properties make it a preferred choice for constructing durable yet portable structures, such as temporary scaffolding or exhibition stands.

In conclusion, the versatility of 1/2 inch aluminum tubing makes it an invaluable resource across various sectors. Its specifications cater to a wide range of applications, ensuring reliability and efficiency in both everyday and specialized uses. As industries continue to seek materials that offer both performance and practicality, aluminum tubing remains a leading contender due to its exceptional properties and adaptability.

When evaluating materials for structural applications, 2x2 aluminum tubing often emerges as a top contender. This type of tubing is particularly valued for its combination of strength, lightweight characteristics, and versatility, making it an excellent choice for a variety of frameworks and supports in both residential and commercial settings.

One of the most significant advantages of 2x2 aluminum square tubing is its load-bearing capacity. Despite its relatively light weight, this tubing can support substantial loads, making it ideal for constructing frameworks that require both strength and portability. For instance, in the construction of temporary structures such as exhibition booths or scaffolding, the balance of weight and strength is crucial. The 6061-T6 aluminum alloy, commonly used in these tubes, offers an impressive tensile strength, ensuring reliability under stress.

2x2 aluminum tubing is widely used in creating structural supports for various applications. Its square profile provides excellent resistance to bending and torsion, making it suitable for building frames, trusses, and load-bearing columns. Additionally, its aesthetic appeal and ease of fabrication make it a popular choice for architectural designs such as railings and decorative elements.

In the transportation industry, this tubing finds use in vehicle frames and support structures, where its lightweight nature contributes to improved fuel efficiency without compromising safety. Similarly, in the marine sector, aluminum's corrosion resistance makes it ideal for constructing boat frames and other components exposed to harsh environments.

When selecting 2x2 aluminum tubing for a project, several factors should be considered. The specific alloy and wall thickness are crucial, as they determine the tubing's strength and flexibility. For applications requiring maximum load-bearing capacity, opting for a thicker wall or a stronger alloy like 6061-T6 is advisable.

Additionally, the environmental conditions in which the tubing will be used should influence material selection. For outdoor applications, the natural corrosion resistance of aluminum provides a significant advantage, ensuring longevity and minimal maintenance.

In conclusion, 2x2 aluminum square tubing offers a versatile and robust solution for a wide range of structural applications. Its ability to provide strength without excessive weight makes it an invaluable material in construction, transportation, and beyond. As industries continue to demand materials that deliver both performance and efficiency, aluminum tubing stands out as a reliable and adaptable choice.

When selecting materials for demanding applications, 6061 aluminum tubing frequently stands out due to its exceptional properties and versatility. This alloy is renowned for its balance of strength, machinability, and excellent corrosion resistance, making it a preferred choice in industries where performance and durability are paramount.

6061 aluminum is a heat-treatable alloy known for its impressive mechanical properties. It provides a tensile strength of at least 45,000 psi and a yield strength of 40,000 psi, which makes it suitable for structural applications requiring high strength. The material's elongation capacity of 12% also ensures flexibility, allowing it to endure stress without fracturing. These characteristics make 6061 aluminum tubing ideal for use in aerospace, automotive, and construction industries where materials must withstand significant loads and stresses.

One of the standout features of 6061 aluminum tubing is its excellent corrosion resistance. The natural formation of a protective oxide layer on its surface effectively shields it from environmental factors such as moisture and chemicals, which can lead to rust and degradation. This property is particularly beneficial in marine and outdoor applications, where exposure to harsh conditions is inevitable. By choosing 6061 aluminum, engineers and designers can ensure longevity and reliability in their projects.

6061 aluminum alloy is celebrated for its high strength-to-weight ratio, which is a critical factor in applications where reducing weight without compromising strength is essential. This characteristic makes it an excellent alternative to heavier metals like steel, offering significant weight savings while maintaining structural integrity. In the transportation industry, for instance, using 6061 aluminum tubing can enhance fuel efficiency and performance by reducing the overall weight of vehicles and aircraft.

Moreover, the alloy's versatility extends to its ease of fabrication and machining. It can be easily cut, welded, and formed into various shapes, accommodating a wide range of design specifications. This adaptability is why 6061 aluminum tubing is extensively used in custom projects, from bicycle frames to architectural elements.

In conclusion, the properties of 6061 aluminum tubing—including its superior mechanical strength, corrosion resistance, and favorable strength-to-weight ratio—make it a highly sought-after material across multiple industries. Its ability to deliver both performance and practicality ensures that it remains a top choice for engineers and designers seeking reliable and efficient solutions for their projects. If you are exploring sizing, bending, or sourcing aluminum tubing for your projects, don't miss our in-depth aluminum tubing guide.

Oval aluminum tubing in innovative furniture and automotive designs (AI-generated)

In the world of industrial and design applications, the choice of tubing can significantly influence both functionality and aesthetics. Oval aluminum tubing, with its distinctive shape and versatile properties, is increasingly becoming a preferred option across various sectors, such as automotive and furniture design. But what makes it stand out compared to traditional round or square profiles?

Oval aluminum tubing offers several benefits that make it an attractive choice for designers and engineers. One of its primary advantages is its enhanced strength-to-weight ratio. The oblong shape provides structural integrity while maintaining a lightweight profile, which is crucial in applications where weight reduction is essential without sacrificing strength. This makes it particularly valuable in the automotive industry, where it is often used in exhaust systems and chassis components to improve aerodynamics and fuel efficiency.

Furthermore, the aesthetic appeal of oval tubing cannot be overstated. Its unique shape adds a modern and sleek look to furniture designs, making it a popular choice for creating contemporary pieces that stand out in any setting. The flattened profile of oval tubing allows for innovative designs that are not only visually appealing but also functional, providing stability and support in furniture structures.

In the automotive sector, oval aluminum tubing enhances fluid dynamics efficiency, which is crucial for components like exhaust pipes. Its aerodynamic shape reduces drag, contributing to better vehicle performance and fuel economy. Additionally, its compact form factor allows for more efficient use of space, which is beneficial in the crowded undercarriage of modern vehicles.

When it comes to furniture design, the oval profile offers a blend of style and functionality. Designers can exploit its unique shape to create furniture that is both lightweight and robust, allowing for easy movement and rearrangement without compromising durability. This makes oval tubing ideal for crafting minimalist furniture that requires less material while providing ample strength and support.

However, it's important to note that working with oval tubing requires precision and expertise. Unlike circular tubes, oval shapes can be more challenging to bend and manipulate without causing deformation. Therefore, employing skilled fabrication techniques is essential to maintain the integrity and appearance of the final product.

In conclusion, oval aluminum tubing offers a range of aesthetic and functional benefits that make it a versatile choice for various applications. Its unique design properties allow for innovative solutions in both automotive and furniture industries, providing a perfect balance of form and function. As industries continue to push the boundaries of design and efficiency, oval aluminum tubing is set to play a pivotal role in shaping the future of industrial and design innovations.

Throughout this comprehensive guide, we've explored the diverse world of aluminum tubing, highlighting its remarkable versatility and the myriad applications across various industries. From its lightweight nature and corrosion resistance to its strength and adaptability, aluminum tubing has proven to be an indispensable material in modern engineering and design.

In the automotive sector, the use of 1/2 OD aluminum tubing as a hard fuel line underscores the material's ability to enhance vehicle performance through weight reduction and corrosion resistance. Similarly, pre-powdercoated aluminum square tubing offers a compelling blend of durability and aesthetic appeal, making it an ideal choice for construction and design projects where both visual and structural integrity are paramount. The adaptability and cost-effectiveness of pre powdercoated aluminum square tubing make it a versatile material for diverse applications.

Our exploration of materials in LG window air conditioners revealed the nuanced decision-making process between using copper and aluminum tubing, each offering distinct benefits in terms of thermal conductivity, cost, and durability. Meanwhile, 1/2 inch aluminum tubing continues to be a versatile solution in plumbing, HVAC systems, and structural components, thanks to its balance of strength and lightweight properties.

For structural applications, 2x2 aluminum square tubing stands out as a robust solution, providing excellent load-bearing capabilities while remaining lightweight. The 6061 aluminum tubing further exemplifies the alloy's superior mechanical properties and corrosion resistance, making it a favored choice in industries requiring a high strength-to-weight ratio.

Moreover, the unique applications of oval aluminum tubing demonstrate how design and functionality can be harmoniously achieved, offering aesthetic benefits in automotive and furniture design while maintaining structural integrity.

As you consider the insights gained from this guide, it's crucial to apply these considerations to your specific projects, ensuring that the choice of aluminum tubing aligns with your functional and aesthetic requirements. For those seeking high-quality aluminum profiles, Anhui Shengxin Aluminum stands as a leading provider, recognized for their extensive production capabilities and commitment to excellence. With their wide range of products and expertise, they are well-equipped to meet the demands of various industries, offering solutions that are both innovative and reliable.

Aluminum tubing is not as strong as steel, but it offers a better strength-to-weight ratio, making it ideal for applications where weight reduction is crucial, such as in aerospace and automotive industries.

Yes, aluminum tubing can be bent by hand with the right tools and techniques, such as a soft jaw vise and a dead blow hammer, allowing for precise shaping without compromising the material's integrity.

The cost of aluminum tubing is driven by energy-intensive production processes and its desirable properties like lightweight and corrosion resistance, making it a valuable material for many applications.

7075-T6 and 2024-T3 are among the strongest aluminum alloys, often used in aerospace for their high-strength properties, offering excellent performance in demanding environments.

1/2 inch aluminum tubing is commonly used in plumbing, HVAC systems, and structural components due to its balance of strength, lightweight, and corrosion resistance.

Servicio en línea

Servicio en línea 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360