Anodized aluminum pipes are a cornerstone in many industries due to their unique properties and versatility. These pipes undergo an electrochemical process known as anodizing, which enhances their natural oxide layer, resulting in improved durability and corrosion resistance. This makes them an ideal choice for applications where longevity and low maintenance are critical, such as in the construction, automotive, and aerospace sectors.

In the aluminum pipe industry , selecting the right supplier is crucial to ensure the quality and performance of the pipes. Reliable anodized aluminum pipe suppliers offer products that meet stringent quality standards, often certified by international regulations. These suppliers provide a range of pipe sizes and shapes, accommodating various industrial needs, and often offer customization options to fit specific project requirements.

Choosing a reputable supplier not only guarantees the quality of the anodized aluminum pipes but also provides access to expert advice and support. This can be invaluable when dealing with complex projects or when specific anodizing specifications are required. By partnering with trusted suppliers, businesses can ensure that their projects are supported by high-quality materials that deliver on performance and reliability.

In conclusion, the significance of anodized aluminum pipes in diverse industries cannot be overstated. Their enhanced properties make them a preferred choice, but it is the supplier's role in delivering quality that ultimately impacts the success of any project. Therefore, selecting the right anodized aluminum pipe suppliers is a strategic decision that can lead to long-term benefits and project success.

When considering materials for industrial applications, the advantages of anodized aluminum cannot be overlooked. This process involves an electrochemical treatment that enhances the natural properties of aluminum, offering a multitude of benefits that make it a preferred choice across various sectors.

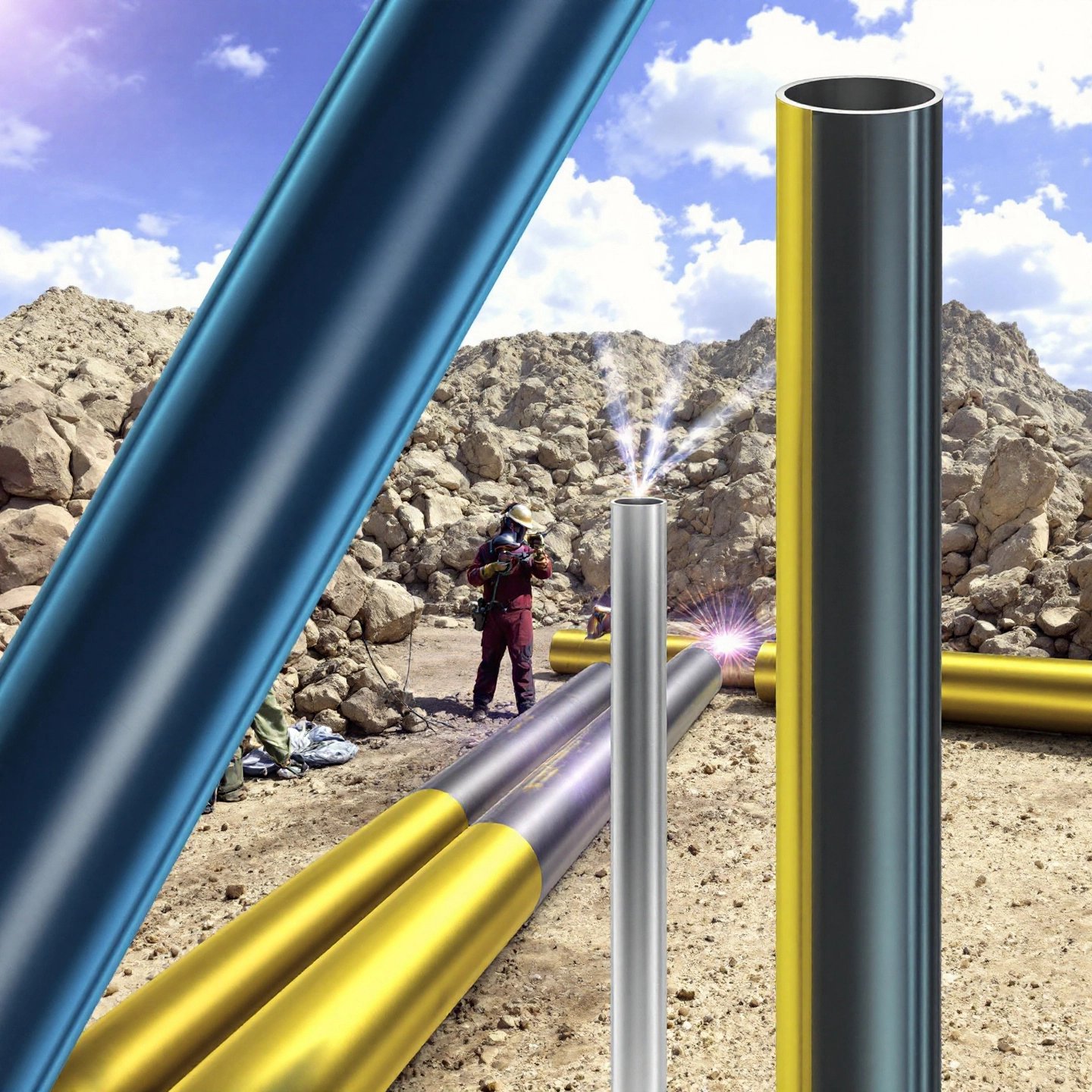

One of the primary benefits of anodized aluminum is its superior corrosion resistance. During anodizing, a protective oxide layer is formed, which acts as a barrier against environmental factors such as moisture, salt, and chemicals. This makes anodized aluminum ideal for use in harsh environments, including marine and outdoor applications where exposure to corrosive elements is a concern. With its enhanced ability to withstand these conditions, anodized aluminum reduces the likelihood of corrosion-related failures, thereby extending the lifespan of the product.

Anodizing significantly increases the surface hardness of aluminum, making it more resistant to abrasion, scratches, and general wear and tear. This added strength ensures that anodized aluminum components maintain their integrity even under heavy usage. Industries such as aerospace and automotive, where components are subjected to rigorous operational stress, benefit greatly from this increased durability. The wear-resistant nature of anodized aluminum translates to lower maintenance costs and less frequent replacements, which is a significant advantage in cost-sensitive projects.

Beyond functional enhancements, anodized aluminum offers aesthetic benefits. The anodizing process allows for the addition of vibrant colors and a smoother, more uniform finish. This is particularly valuable in applications where both performance and appearance are important, such as architectural finishes and consumer electronics. The ability to maintain a sleek, metallic finish without compromising structural integrity makes anodized aluminum a versatile material for decorative purposes.

In conclusion, the benefits of anodized aluminum extend far beyond basic corrosion resistance. Its enhanced durability, aesthetic versatility, and reduced maintenance needs make it an invaluable material in industries that demand high performance and reliability. By choosing anodized aluminum pipes, businesses can ensure long-term success and operational efficiency.

Anodized aluminum pipes are integral to numerous industries, thanks to their enhanced properties and versatility. Their applications span across sectors such as construction, automotive, aerospace, and marine, where they play crucial roles in various capacities.

In construction, anodized aluminum pipes are highly valued for their durability and corrosion resistance. They are commonly used in structural components, window frames, and cladding materials. The lightweight nature of aluminum, combined with its strength, makes it ideal for modern architectural designs that require both aesthetic appeal and structural integrity. Additionally, the anodized finish provides an attractive appearance with minimal maintenance, which is crucial for building exteriors exposed to the elements.

The automotive industry leverages anodized aluminum pipes in exhaust systems, chassis components, and decorative trims. The enhanced durability and resistance to corrosion ensure these components perform reliably under the harsh conditions of road use. Furthermore, the lightweight characteristic of aluminum contributes to improved fuel efficiency, which is increasingly important in the era of environmental sustainability.

In aerospace, the use of anodized aluminum is prevalent due to its excellent strength-to-weight ratio. It is utilized in aircraft fuselages, wing structures, and interior components where weight reduction is critical. Anodized aluminum's ability to withstand extreme environmental conditions without compromising structural integrity is invaluable in aerospace engineering. This is particularly evident in applications such as the skin of aircraft, where both durability and weight are paramount.

For the marine sector, anodized aluminum pipes are used in boat fittings, masts, and railings. The superior corrosion resistance of anodized aluminum is essential in marine environments, where exposure to saltwater can rapidly degrade other materials. This resistance ensures longevity and reduces maintenance costs, making it a preferred choice for marine applications.

In summary, the diverse applications of anodized aluminum pipes across various industries highlight their importance and versatility. Whether in construction, automotive, aerospace, or marine sectors, these pipes provide the durability, aesthetic appeal, and performance required for demanding industrial uses. Their widespread adoption underscores the pivotal role they play in modern engineering and design.

When selecting an anodized aluminum pipe supplier, several critical factors should guide your decision to ensure you receive high-quality products and reliable service. Here are the key considerations:

First and foremost, ensure that the supplier adheres to stringent quality standards. Look for certifications such as ISO 9001, which indicate a commitment to quality management systems. A supplier with robust quality assurance processes will provide products that consistently meet or exceed industry requirements, reducing the risk of defects and ensuring long-term performance.

The range of products a supplier offers is another important factor. A comprehensive product catalog, including various sizes, shapes, and grades of anodized aluminum pipes, allows you to find the exact specifications needed for your project. Suppliers like Kloeckner Metals offer a wide array of aluminum products, ensuring you have access to the necessary materials without having to engage multiple vendors.

Customization capabilities are essential if your project requires specific dimensions or finishes. Suppliers with advanced fabrication services can provide tailored solutions, including cutting, bending, and finishing options. This flexibility ensures that the pipes fit perfectly within your project's framework, enhancing both functionality and aesthetics.

Timely delivery is crucial for maintaining project schedules. Evaluate the supplier’s lead times and their ability to meet deadlines. A reliable supplier will offer realistic timelines and have contingency plans in place to address potential delays, ensuring your project progresses smoothly.

Excellent customer support is invaluable. Choose a supplier that offers responsive and knowledgeable service, assisting you throughout the purchasing process and beyond. This includes helping with product selection, addressing any issues that arise, and providing technical support when needed.

Ultimately, choosing the right anodized aluminum pipe supplier involves balancing these factors to find a partner that aligns with your project’s needs and values. By prioritizing quality, variety, customization, timely delivery, and support, you can ensure a successful partnership that contributes to your project's success.

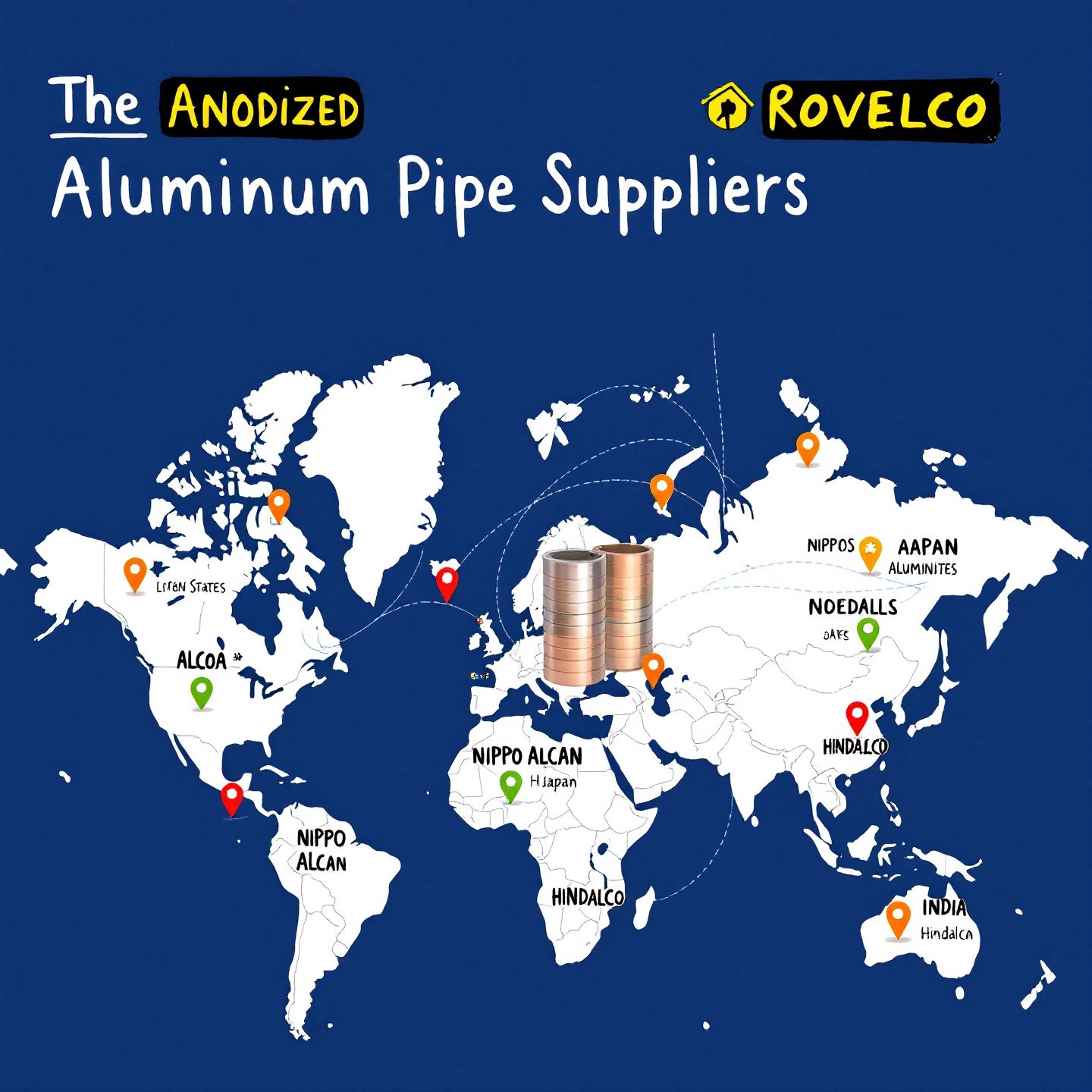

In the competitive landscape of anodized aluminum pipe suppliers, identifying the top players can significantly impact the success of your projects. These suppliers are distinguished by their commitment to quality, innovation, and comprehensive product offerings, which cater to a wide array of industrial needs.

Among the leading suppliers, Shengxin Aluminum stands out due to its extensive experience and diverse product range. Established in 2003, Shengxin has grown to become the largest aluminum profiles manufacturer in Anhui Province, China. The company offers more than 100 production lines, including fusion casting, extrusion, anodizing, and many more. Shengxin's commitment to quality is evident in its ISO certifications and its ability to meet the high standards required for automotive and aerospace applications.

Shengxin's extensive product line includes unit-type and frame-type eco-friendly profiles, energy-saving window and door profiles, and high-tech industrial profiles for new energy vehicles and rail transit. This diverse range ensures that clients receive tailored solutions that meet their specific project requirements.

Several other suppliers also make significant contributions to the industry:

These suppliers, along with Shengxin Aluminum, exemplify the qualities essential in leading anodized aluminum pipe suppliers: innovation, a broad product range, and a commitment to quality. When selecting a supplier, consider these attributes to ensure that your projects benefit from the best in the industry.

Choosing a reputable supplier like Shengxin Aluminum not only ensures product quality but also provides access to advanced technical support and customized solutions tailored to your project's specific needs. By partnering with such industry leaders, businesses can achieve superior results and maintain a competitive edge in their respective fields.

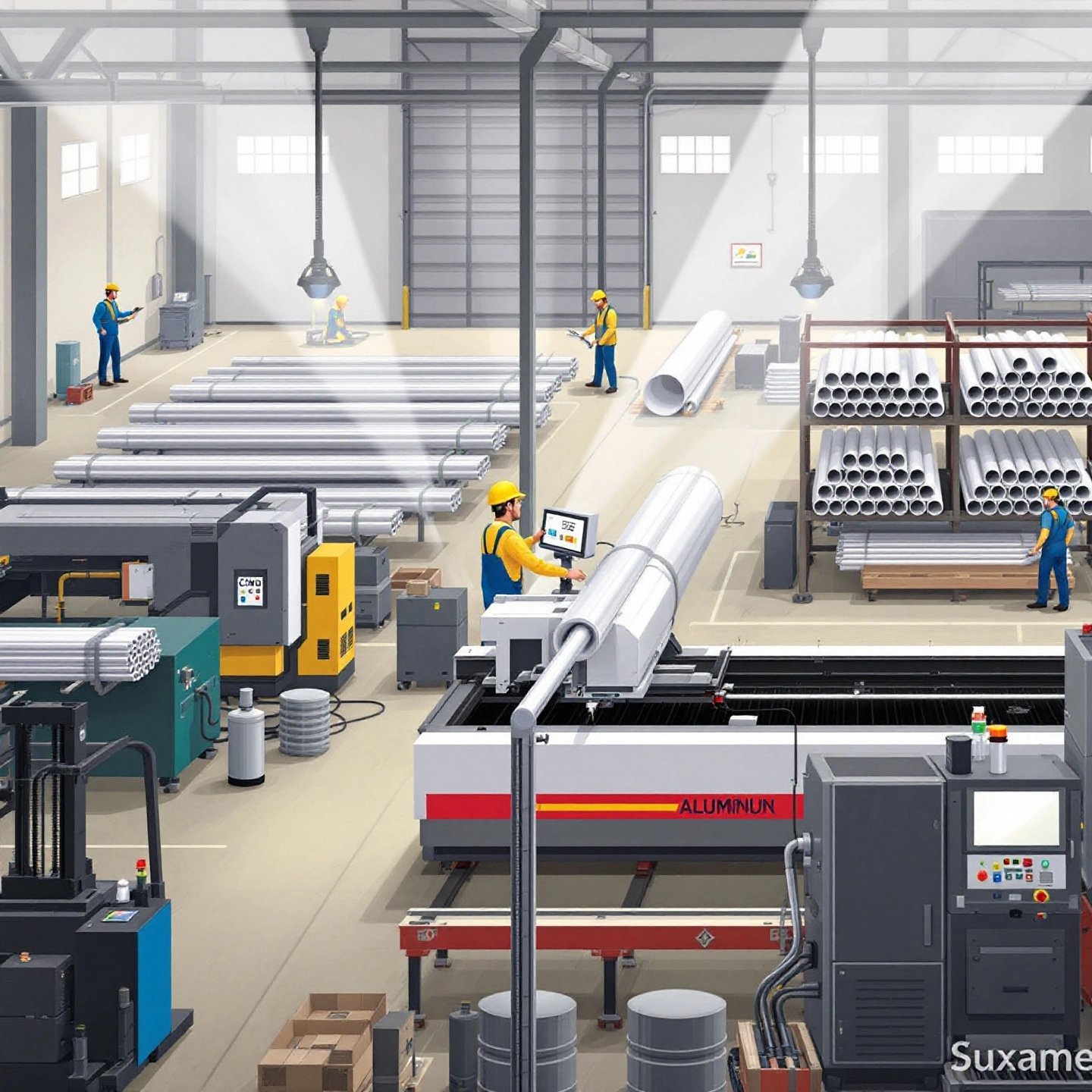

When it comes to selecting anodized aluminum pipe suppliers, the ability to customize and fabricate products to meet specific project requirements is crucial. Customization ensures that the aluminum pipes fit perfectly within the unique parameters of your project, enhancing both functionality and aesthetics. Reliable suppliers offer a range of aluminum customization services that include cutting, bending, and finishing, which are essential for tailoring products to precise specifications.

Imagine embarking on a complex construction project where every component must align perfectly to maintain the structural integrity and design vision. Customization in aluminum pipes allows for such precision, ensuring that each piece contributes to the overall success of the project. It provides the flexibility to adjust dimensions, shapes, and finishes, catering to diverse industrial applications. This is particularly significant in sectors like aerospace, automotive, and construction, where specific requirements are non-negotiable.

Suppliers typically offer a suite of fabrication services, each critical to achieving the desired product specifications:

Among the top suppliers, Shengxin Aluminum offers advanced customization and fabrication capabilities. With a comprehensive range of services, Shengxin ensures that each aluminum pipe meets exacting standards. Their expertise in anodizing and other finishing techniques allows for superior product performance and aesthetic appeal. For more detailed insights into their offerings, you can explore this blog .

In conclusion, the ability to customize and fabricate aluminum pipes to meet specific project needs is a vital service offered by leading suppliers. By choosing a supplier like Shengxin Aluminum, businesses can leverage advanced capabilities to ensure their projects are executed with precision and excellence.

In the realm of anodized aluminum pipe production, quality assurance is not just a procedural formality but a critical pillar that ensures the reliability and performance of the final product. Quality assurance processes involve systematic monitoring, inspection, and improvement at every stage of manufacturing, from raw material selection to the final product delivery. But why is this so important?

Imagine embarking on a large-scale construction project only to find that the aluminum pipes delivered do not meet the specified standards. This could lead to structural failures, costly delays, and reputational damage. Quality assurance mitigates such risks by ensuring that every pipe meets the required specifications and industry standards. By catching defects early, manufacturers can reduce waste, improve efficiency, and maintain consistency, which is vital in high-stakes industries like aerospace and automotive.

When selecting anodized aluminum pipe suppliers, certifications serve as a testament to a company's commitment to quality. One of the most recognized certifications is the ISO 9001, part of the ISO 9000 family, which focuses on quality management systems. This certification indicates that a supplier adheres to rigorous quality management principles, ensuring consistent product quality and customer satisfaction. According to Clinton Aluminum , ISO certification also facilitates international trade by providing a common quality benchmark recognized worldwide.

Besides ISO 9001, other certifications such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) are crucial for suppliers serving the aerospace and defense sectors. These certifications ensure that the manufacturing processes meet the stringent requirements necessary for safety and performance in these industries.

By prioritizing suppliers with robust quality assurance processes and relevant certifications, businesses can safeguard their projects against unforeseen complications. This not only enhances the reliability of the supply chain but also ensures that the final products are of the highest quality, meeting both functional and regulatory requirements. In the competitive landscape of anodized aluminum pipe suppliers, certifications are a key differentiator that can influence purchasing decisions and project outcomes significantly.

In summary, quality assurance and certifications are indispensable in the manufacturing of anodized aluminum pipes. They provide a framework for maintaining high standards, ensuring that the products delivered are reliable and fit for purpose. As you evaluate potential suppliers, consider these factors to make informed decisions that align with your project goals.

Throughout this article, we've explored the critical aspects of choosing anodized aluminum pipe suppliers, emphasizing the importance of making informed decisions to ensure quality and project success. As we've seen, anodized aluminum pipes offer significant advantages due to their enhanced corrosion resistance, durability, and aesthetic appeal, making them a preferred choice across various industries.

When selecting an aluminum supplier , it's crucial to consider factors such as quality standards, product range, customization capabilities, and lead times. These elements ensure that you receive products that meet your specific project requirements and are delivered on schedule. Moreover, the importance of customer support cannot be overstated, as it plays a vital role in facilitating smooth transactions and addressing any concerns promptly.

Among the leading suppliers, Shengxin Aluminum stands out for its extensive experience and diverse product offerings. With over 100 production lines and a commitment to high-quality standards, Shengxin Aluminum provides tailored solutions that cater to the unique needs of various sectors, including construction, automotive, aerospace, and marine industries. Their dedication to quality assurance and comprehensive certifications further underscores their reliability as a supplier.

In conclusion, prioritizing the selection of reputable suppliers like Shengxin Aluminum not only guarantees the quality of anodized aluminum pipes but also ensures access to expert advice and support. By doing so, businesses can achieve superior results, maintain a competitive edge, and ensure the success of their projects. The significance of choosing the right supplier cannot be overstated, as it directly impacts the quality and reliability of the final product, ultimately determining the project's overall success.

Anodized aluminum pipes offer enhanced corrosion resistance, increased durability, and improved aesthetic appeal, making them ideal for various industries.

Consider factors like quality standards, product range, customization capabilities, lead times, and customer support to ensure you select a reliable supplier.

Customization ensures that aluminum pipes meet specific project requirements, enhancing functionality and aesthetics, especially in industries like aerospace and construction.

Industries such as construction, automotive, aerospace, and marine commonly use anodized aluminum pipes due to their durability and resistance to corrosion.

Look for certifications like ISO 9001 and NADCAP, which indicate adherence to rigorous quality management and manufacturing standards, ensuring product reliability.

Servicio en línea

Servicio en línea 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360