Have you ever wondered why aluminum foil doesn’t melt in your oven, but transforms into a liquid in a foundry? The answer lies in a fundamental property known as the melting point of aluminum. This single number—expressed in degrees Celsius or Fahrenheit—has far-reaching implications, from the design of your smartphone’s casing to the recycling of beverage cans and the construction of aircraft.

Let’s start with the basics. A melting point is the temperature at which a solid turns into a liquid under standard atmospheric pressure. At this precise temperature, both the solid and liquid forms of a pure substance coexist in equilibrium. For most crystalline solids, including metals like aluminum, this is a highly specific temperature that helps scientists and engineers identify and characterize materials. In mixtures or alloys, the melting process often occurs over a range of temperatures rather than at a single point (Britannica).

Understanding the melting point of aluminum—especially the melting point of aluminum in celsius—isn’t just a trivia question. It’s a cornerstone for:

In this article, you’ll discover:

Whether you’re a student, engineer, or simply curious about how things are made, understanding the melting point of aluminum is your entry point to mastering its role in modern technology, sustainability, and innovation. Let’s dive in and unlock the secrets behind this essential metal’s melting behavior.

Ever noticed how a soda can seems indestructible in your kitchen oven, yet pure aluminum transforms into a silvery liquid at a specific temperature? That’s because the melting point of aluminum is not just a random number—it’s a scientifically established constant that defines how this metal behaves in its purest form.

In its pure, elemental state, aluminum melts at 660.3°C (1220.5°F) under standard atmospheric pressure. You might also see this rounded to 660°C (1220°F) in many engineering references. This value is so reliable that it’s used as a benchmark in laboratories and industrial processes worldwide.

Imagine placing a bar of pure aluminum in a precisely controlled furnace. As the temperature rises, nothing dramatic happens—until you reach exactly 660.3°C (or 1220.5°F). At that moment, the solid metal abruptly turns to liquid. This sharp transition is a hallmark of pure substances, unlike alloys or mixtures, which melt over a range.

This melting point is considered a fundamental physical constant for aluminum. It’s used as a reference in material science, quality control, and even in calibrating high-precision instruments. But what makes this number so dependable?

In summary, the melting point of aluminum—660.3°C or 1220.5°F—is more than just a number. It’s a cornerstone for everything from material selection to quality assurance in high-tech industries. As you’ll see in the next section, everyday aluminum products like foil and cans don’t always follow this rule, thanks to alloying and impurities. So, what happens when you heat up the aluminum in your kitchen? Let’s find out.

Ever wondered why your aluminum foil stays intact in a hot oven or why empty soda cans don’t melt on a backyard grill? The answer lies in the melting behavior of everyday aluminum products—and it’s not just about the metal itself, but also what’s mixed in. Let’s break down how common household items like foil and cans respond to heat, and what this means for recycling, cooking, and beyond.

It might seem surprising that thin aluminum foil or beverage cans don’t simply liquefy when exposed to high temperatures in the kitchen. That’s because the melting point of aluminum foil and melting point of aluminum cans are both determined by the same core property: the intrinsic melting point of aluminum, which is 660°C (1,220°F). However, the story gets more interesting when you consider the role of alloying and product design.

In summary, the melting behavior of everyday aluminum products is a balance between the metal’s natural properties and the specific alloying choices made during manufacturing. Next, we’ll explore how alloying elements can further influence aluminum’s melting range and why this matters for specialized applications.

Ever wondered why not all aluminum melts at the same temperature? If you’ve worked with aluminum in any form—be it parts, profiles, or castings—you’ll notice that the melting point of aluminum alloys isn’t a fixed number like pure aluminum. Sounds complex? Let’s break it down and see how alloying transforms both the science and the possibilities of aluminum.

Imagine you’re baking cookies with different types of chocolate chips; some melt sooner, others hold their shape. That’s similar to what happens when aluminum is mixed with other elements. Pure aluminum has a precise melting point of 660.3°C (1220.5°F), but when alloyed with elements like magnesium, silicon, copper, or zinc, the result is a blend where each ingredient influences how—and when—the alloy melts.

Instead of a sudden transition from solid to liquid, aluminum alloys melt gradually over a temperature range. This is defined by two critical points:

Between these temperatures, the alloy exists as a mix of solid and liquid. This behavior is crucial for casting, welding, and extrusion, where precise control ensures quality and performance.

The melting point of aluminum alloy depends on which elements are added and in what proportions. Here’s a look at how common alloying elements shift the melting range:

| Alloy Series / Main Alloying Element | Typical Melting Range (°C) | Typical Melting Range (°F) | Key Properties |

|---|---|---|---|

| 1xxx (Pure Aluminum) | 660 | 1220 | Highest purity, electrical applications |

| 2xxx (Aluminum-Copper) | 548 | 1018 | High strength, lower melting point |

| 3xxx (Aluminum-Manganese) | 640–655 | 1184–1211 | Good corrosion resistance |

| 4xxx (Aluminum-Silicon) | 577 | 1070 | Excellent castability |

| 5xxx (Aluminum-Magnesium) | 605–650 | 1121–1202 | High strength, marine uses |

| 6xxx (Al-Mg-Si) | 580–650 | 1076–1202 | Versatile, widely extruded |

| 7xxx (Aluminum-Zinc) | 475–635 | 887–1175 | Ultra-high strength, aerospace |

As you can see, adding copper or zinc tends to lower the solidus point, while magnesium or manganese can broaden the range. The result? Each alloy can be tailored for specific strength, flexibility, or corrosion resistance—making aluminum alloys the backbone of everything from beverage cans to skyscraper frames.

Understanding the melting range of an aluminum alloy is essential for:

For manufacturers and engineers, selecting the right alloy—and knowing its melting characteristics—means fewer defects, better performance, and more efficient processes.

When you need expertise in matching alloy composition to application, it pays to partner with specialists. Shengxin Aluminum offers advanced temperature control and deep knowledge of alloy behavior, ensuring every extrusion or casting meets strict industry standards. Their comprehensive blog post on melting point of aluminum alloys is a valuable resource for innovators and engineers alike.

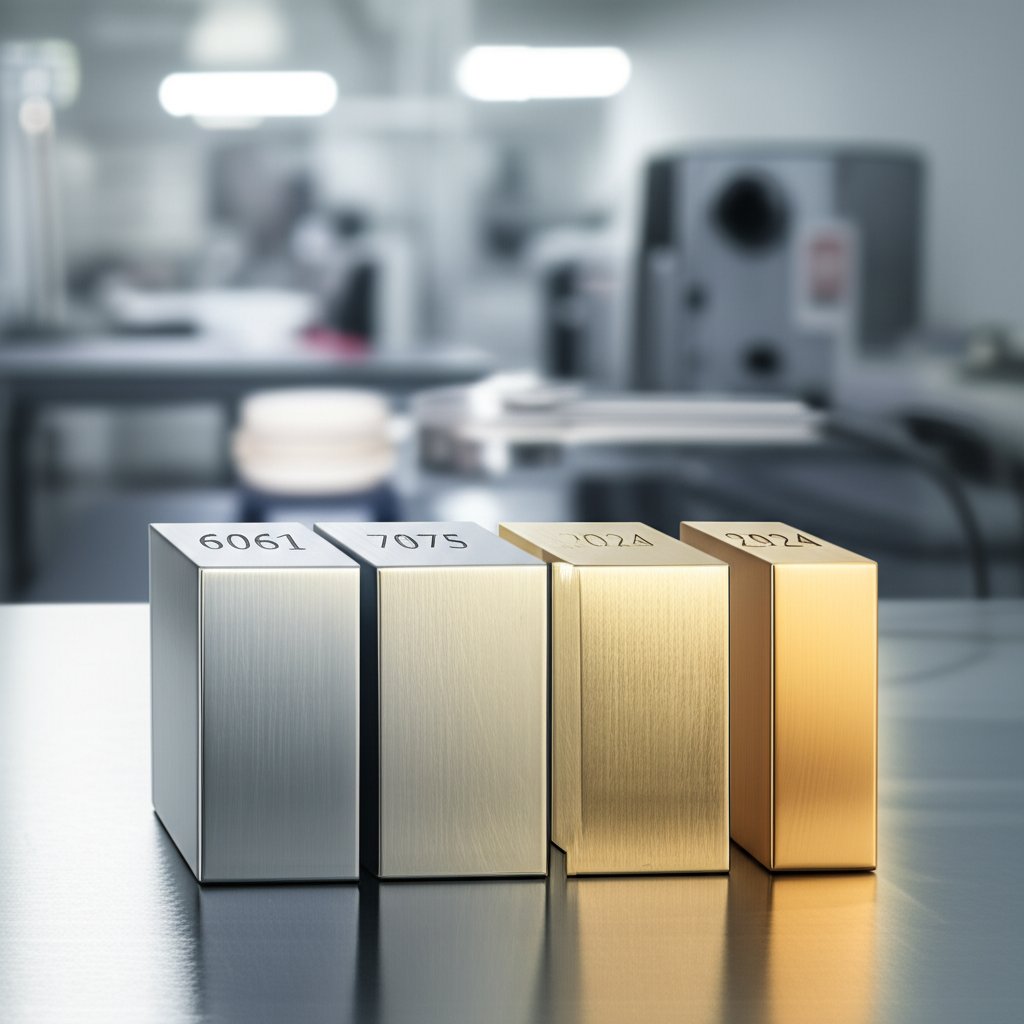

Now that you know how alloying shapes the melting range, let’s zoom in on two of the most important industrial aluminum alloys—6061 and 7075—and see how their specific compositions influence their melting behavior and real-world uses.

When you hear about aluminum in high-performance engineering, two grades stand out: 6061 and 7075. But what makes these alloys the go-to choices for everything from bicycle frames to aircraft wings? The secret lies not just in their strength, but in how their unique compositions influence their melting points and processing behavior. Curious how the melting point of aluminum-6061 compares to the melting point of 7075 aluminum? Let’s break it down so you can see why these alloys matter in industry—and how to choose the right one for your project.

Imagine you’re designing a part that needs to withstand heat, pressure, and the test of time. The alloy you select will determine not only its strength, but also how it behaves during welding, machining, and heat treatment. Here’s how 6061 and 7075 stack up:

| Alloy | Main Alloying Elements | Melting Range (°C) | Melting Range (°F) | Notable Features |

|---|---|---|---|---|

| 6061 | Magnesium, Silicon | 582–652 | 1080–1206 | Excellent weldability, corrosion resistance, versatile |

| 7075 | Zinc, Magnesium, Copper | 477–635 | 891–1175 | Ultra-high strength, good fatigue resistance, less weldable |

Unlike pure aluminum, these alloys don’t melt at a single temperature. Instead, they soften and liquefy over a range, which is crucial for manufacturing:

So, how do you decide between 6061 and 7075? It’s all about your priorities:

For engineers and manufacturers seeking consistent quality and expert guidance, working with a trusted supplier makes all the difference. Shengxin Aluminum specializes in producing high-quality 6061 and 7075 aluminum profiles, combining advanced melting and extrusion technologies with deep industry know-how. Their technical support can help you navigate the nuances of alloy selection, ensuring your project meets both performance and budget goals.

Next, let’s clarify how to express melting temperatures in both Celsius and Fahrenheit—and why getting the units right is critical in technical discussions.

Ever found yourself puzzled when one resource lists the melting point of aluminum in Celsius and another in Fahrenheit? You’re not alone. In global industries and scientific research, temperature scales matter—a lot. Let’s break down how to confidently express and convert aluminum’s melting point, so you never mix up your units or misinterpret critical data.

Whether you’re reading a technical datasheet or a recycling guide, you’ll see both figures used. This is because Celsius (°C) is standard in most of the world and scientific communities, while Fahrenheit (°F) remains common in the United States and some engineering fields.

Sounds complex? It’s actually straightforward. If you know the melting point in one unit, you can switch to the other using a simple formula:

For example, to check the melting point of aluminum in Fahrenheit:

These formulas ensure accuracy, especially when comparing technical data from different countries or industries (ThoughtCo).

Imagine ordering a batch of aluminum, only to realize your supplier uses a different temperature scale. Confusing Celsius and Fahrenheit could lead to costly errors—like overheating, damaging equipment, or compromising product quality. That’s why it’s best practice to always:

By getting the units right, you ensure safety, efficiency, and global clarity—no matter where your aluminum journey takes you. Next, let’s see how aluminum compounds like oxides and bronzes compare in their melting behavior.

When you think of the melting point of aluminum, you might picture silvery metal flowing in a foundry. But what happens when aluminum is combined with other elements to form compounds or specialized alloys? The answer: melting points can change dramatically, and so do their industrial roles. Let’s explore how the melting point of aluminum oxide, melting point of aluminum bronze, and related materials compare to pure aluminum—and why these differences matter for real-world applications.

Imagine a material that can withstand temperatures far beyond what most metals can handle. That’s aluminum oxide (Al2O3), also known as alumina. Unlike metallic aluminum, which melts at 660°C (1220°F), aluminum oxide melts at about 2,000°C (3,632°F). This huge jump in melting point is due to the strong ionic bonds between aluminum and oxygen atoms, creating a structure that resists breaking down under heat.

Now, consider aluminum bronze—an alloy primarily made of copper with 5% to 12% aluminum, plus possible additions of iron, nickel, or manganese. The melting point of aluminum bronze typically falls between 1027°C (1881°F) and 1038°C (1900°F), depending on its precise composition. That’s substantially higher than pure aluminum, and even higher than some aluminum alloys.

What about aluminum brazing rods? These are formulated to melt at temperatures slightly below those of the base aluminum alloy, typically in the range of 500°C to 600°C (932°F to 1112°F), allowing for effective joining without melting the structural pieces themselves. The exact melting range depends on the rod’s composition, which often includes silicon or zinc to lower the melting point and improve flow.

Understanding these differences helps engineers select the right material for each job—whether it’s withstanding furnace heat, surviving salty seas, or creating reliable joints. Next, we’ll see how aluminum’s melting point compares to other common metals, and what that means for energy use and high-temperature design.

When you’re choosing materials for a project—or just curious about why certain metals are used for specific jobs—their melting points are a big deal. Ever wondered why aluminum is favored for beverage cans, but steel is chosen for skyscraper beams? Or why copper is used in wiring, but not in aircraft frames? The answer often comes down to how each metal behaves under heat. Let’s put the melting point of aluminum vs steel, copper, and other familiar metals side by side, so you can see exactly how they stack up and why it matters for real-world applications.

To make this easy to compare, here’s a table showing the melting points of aluminum, steel, copper, iron, lead, tin, and titanium. All values are based on reliable engineering data:

| Metal | Melting Point (°C) | Melting Point (°F) | Typical Applications |

|---|---|---|---|

| Aluminum (Pure) | 660 | 1220 | Cans, foil, aircraft, automotive parts |

| Lead | 328 | 621 | Batteries, weights, radiation shielding |

| Tin | 232 | 449 | Coatings, solder, packaging |

| Copper | 1084 | 1983 | Electrical wiring, plumbing, heat exchangers |

| Iron (Cast) | 1127–1204 | 2060–2200 | Pipes, cookware, machinery |

| Steel (Carbon) | 1371–1593 | 2500–2900 | Construction, tools, automotive frames |

| Stainless Steel | 1510 | 2750 | Kitchenware, medical devices, architecture |

| Titanium | 1670 | 3040 | Aerospace, medical implants, high-performance parts |

Why does this matter for industry and the environment? Melting point directly affects the energy required for manufacturing and recycling. For example:

So, when you’re weighing the pros and cons of different metals, remember: a lower melting point can mean easier processing and greener recycling, while a higher melting point unlocks performance in the hottest, toughest environments.

Next, let’s go beyond melting and look at aluminum’s boiling point and other key thermal properties that complete the picture of this versatile metal.

When talking about aluminum’s behavior under heat, it’s not just the melting point that matters. Have you ever wondered what happens if you keep heating aluminum past its liquid state? Or why it’s such a popular choice for cookware and heat exchangers? Let’s explore the melting and boiling point of aluminum, and see how these numbers—along with thermal conductivity—shape aluminum’s role in science and industry.

If you heat pure aluminum beyond its melting point of 660°C (1,220°F), it remains a liquid until it reaches an impressive boiling point of 2,467°C (4,473°F). That’s nearly four times its melting temperature! This wide gap between melting and boiling points is significant for several reasons:

Another standout property is aluminum’s high thermal conductivity. With a value of about 237 W/m·K (watts per meter per kelvin) (PMC), aluminum is an excellent conductor of heat—second only to copper among common metals. This means:

In short, while the melting point of aluminum is essential for processing, its high boiling point and outstanding thermal conductivity are what make it such a versatile, reliable, and energy-efficient material. Next, we’ll wrap up by summarizing these key insights and offering guidance on choosing the right aluminum for your needs.

When you reflect on the journey through the science and applications of the melting point of aluminum, it’s clear this property is far more than a number on a datasheet. So, what have we learned—and how can you use this knowledge to make smarter decisions in engineering, manufacturing, or even your daily life?

Imagine you’re developing a new product or planning a large-scale build. The right aluminum choice—supported by a deep understanding of melting behavior—can mean the difference between long-term success and unexpected failure. That’s why partnering with a manufacturer who truly understands the science is so valuable.

For those seeking reliable, high-quality aluminum solutions, Shengxin Aluminum stands out with its technical expertise and full-spectrum production capabilities. With decades of experience, a robust technical team, and a commitment to innovation, Shengxin Aluminum delivers custom alloys and profiles tailored to your exact requirements. Whether you need precision for aerospace, durability for construction, or efficiency for automotive applications, their knowledge of melting point science and alloy behavior ensures optimal results (Learn more).

In summary, mastering the melting point of aluminum is your gateway to unlocking its full potential. By leveraging this knowledge—and working with trusted partners like Shengxin Aluminum—you’re equipped to drive innovation, efficiency, and sustainability in every project.

Aluminum foil has a melting point of about 660°C (1,220°F), the same as pure aluminum. Standard kitchen ovens and grills operate well below this temperature, so foil remains solid during regular cooking and baking tasks.

Tungsten has the highest melting point of all metals at 3,422°C (6,192°F), making it extremely resistant to melting under normal conditions. In comparison, aluminum melts at a much lower temperature, making it easier to process and recycle.

Knowing the melting point of aluminum is essential for processes like casting, welding, and extrusion. It ensures the metal is heated to the correct temperature for shaping without causing defects or wasting energy, resulting in better product quality and efficiency.

Adding elements like magnesium, silicon, copper, or zinc to aluminum creates alloys that melt over a range rather than a single temperature. Each alloy’s composition can lower or broaden the melting range, allowing for tailored properties in applications like aerospace or automotive manufacturing.

The melting point of pure aluminum is 660.3°C (1,220.5°F), where it transitions from solid to liquid. Its boiling point is much higher, at 2,467°C (4,473°F), where the liquid aluminum turns to vapor. This wide gap allows aluminum to be used in various high-temperature processes without risk of vaporization.

Servicio en línea

Servicio en línea 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360